- You are here:

- Home /

- Products /

- Stainless Steel /

- Stainless Steel Wire

Premium Stainless Steel Wire for Industrial & Precision Use

Stainless steel wire in coils, spools or straight cuts. Used for welding, spring making, wire mesh, heating, tying and more. Factory prices and fast delivery.

What Is Stainless Steel Wire?

Stainless steel wire is a high-strength, corrosion-resistant metal product used in diverse industries ranging from welding and electronics to construction and packaging.

It is available in multiple conditions and forms:

Soft wire (annealed) – for tying, shaping, weaving

Hard wire – for spring or tensioning

Spring wire – high tensile, fatigue-resistant

Welding wire – for MIG/TIG filler materials

Fine wire / thin wire – electronics, cables

Flat or profiled wire – special shaped applications

Available in spools, coils, and straight lengths.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

309Si2 High-Temperature Austenitic Stainless Steel Plate

You are here: Home /

Optional product specifications

| Property | Details |

|---|---|

| Grades | 201, 202, 304, 304L, 316, 316L, 430, etc. |

| Diameter | 0.02mm – 10mm |

| Surface Finish | Bright, matte, pickled, electrolytic polished |

| Tensile Strength | 350 – 2100 MPa (depending on temper) |

| Condition | Soft, Half Hard, Hard, Spring Temper |

| Packing Forms | Coil, spool, bobbin, straight bar |

| Standards | ASTM A580 / EN10270-3 / JIS G4314 |

* Support for custom cut lengths, spooling, oil coating or color marking.

Performance Characteristics and Applications of Stainless Steel Wire

1. Performance Characteristics

1.1 Corrosion Resistance

Stainless steel wire is primarily austenitic, with added chromium, nickel, and other elements forming a passivation film. This effectively resists corrosion from oxidation, acid rain, and high-salt environments, making it particularly suitable for coastal or chemical applications.

1.2 Mechanical Properties

High Strength: Cold rolling imparts high tensile strength, making it suitable for components subjected to dynamic loads.

Elasticity and Toughness: Stress can be released through heat treatment, maintaining stable elasticity, suitable for applications subject to repeated deformation.

Abrasion Resistance: Bright surface treatment or plating protects the surface, reducing friction loss and extending service life.

1.3 Processing Adaptability

Supports winding, welding, bending, and other processes, and can be customized into complex shapes such as flat wires and springs.

Lubricating coatings or nickel plating improve forming accuracy and reduce processing damage.

2. Main Applications

2.1 Industrial Manufacturing

Automotive and Machinery: Used for controlling tensile components such as cable cores and springs, enhancing structural stability.

Fasteners: Used as raw materials for screws and bolts, meeting the high-strength requirements of shipbuilding, aerospace, and other fields.

2.2 Precision Instruments

Orthodontic Treatment: Utilizing its rigidity and elasticity, dental archwires correct teeth and maintain arch stability.

Electronic Components: Woven metal mesh or precision springs used for conductive and buffering components in electrical appliances and instruments.

2.3 Environmental Protection and Construction

Sealing Materials: Customized processing into gaskets and filters, with corrosion resistance suitable for chemical equipment.

Decorative Structures: Surface finish supports artistic designs, used for durable decorations such as railings and curtain walls.

Processing & Packaging

Wire drawing & straightening

Annealing & hardening

Electro-polishing & acid pickling

Spool packing (plastic, metal, wooden)

Coil packing with PVC, woven bag, crate

Straight cut bar + PE wrap + bundled

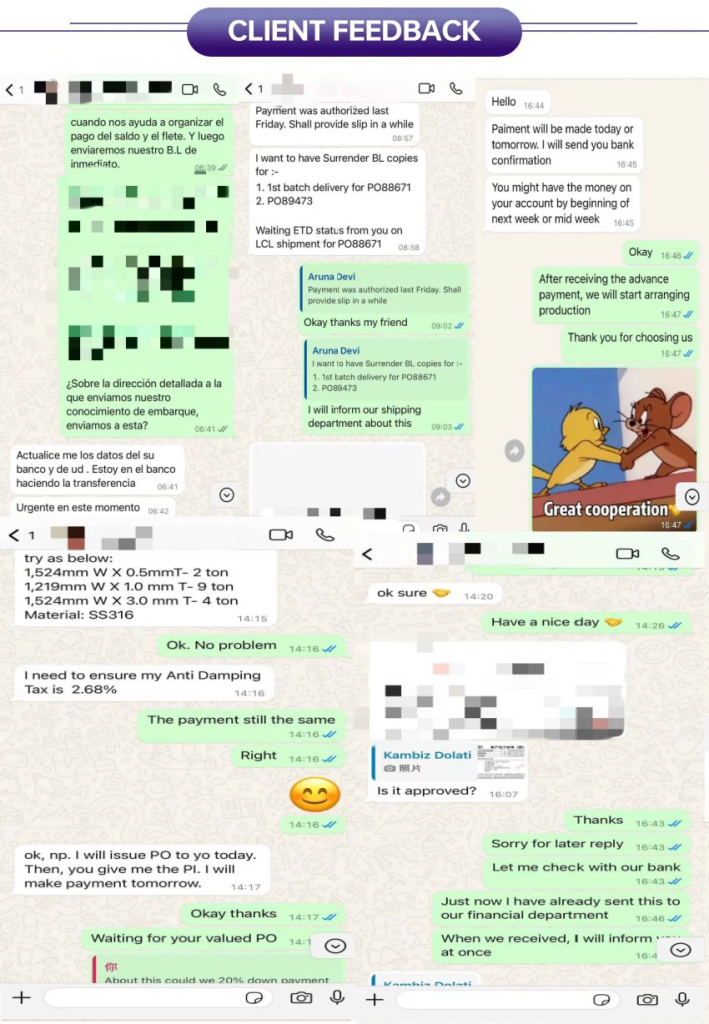

Why Buy From Xishang?

- Wide diameter range from 0.02mm to 10mm

- Multiple tensile options for different uses

- Electrolytic polished & oil-coated options

- Flexible MOQ – even 1 spool or coil accepted

- Factory-direct pricing with SGS/BV/ISO certifications

- Short lead time for both stock and custom wires

Frequently Asked Questions

Q1: What’s the difference between soft and spring wire?

A:

Soft wire is annealed and bendable, used for tying and weaving. Spring wire is hardened and used for load-bearing or repeated bending.

Q2: Do you supply fine wire for cable or filter mesh?

A:

Yes. We offer ultra-fine stainless wire (as thin as 0.02mm) for precision weaving and electronics.

Q3: Can you customize wire tensile strength?

A:

Yes. We offer hard, medium, and spring temper wires based on application needs.

Q4: Is the wire suitable for welding applications?

A:

Absolutely. We provide MIG and TIG filler wire in 304, 308L, 316L with clean spooling and surface condition.

Q5: What’s your packaging standard?

A:

Spool packing, coils with plastic or wooden carriers, and PE-wrapped straight rods with steel bundling.