- You are here:

- Home /

- Products /

- Stainless Steel /

- Stainless Steel Pipe

High-Quality Stainless Steel Pipe & Tube for Industrial Use

Welded and seamless stainless steel pipes in 304, 316L, and other grades for construction, fluid transport, and structural applications.

What Are Stainless Steel Pipes & Tubes?

Stainless steel pipes and tubes are long, hollow sections used for fluid transport, structural support, or decorative use. They are valued for their corrosion resistance, durability, and clean finish.

The key difference:

Pipes are generally used for transporting fluids or gases (focus on pressure & internal diameter)

Tubes are often structural or decorative (focus on outer dimensions & finish)

Available in round, square, and rectangular shapes and used in construction, chemical plants, marine structures, furniture, and mechanical systems.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Grades | 201, 202, 304, 304L, 316, 316L, 310S, 321, 430, 2205, 2507 |

| Types | Seamless / Welded (ERW, TIG, Laser Welded) |

| Shapes | Round, Square, Rectangular |

| Outer Diameter | 6mm – 630mm |

| Wall Thickness | 0.5mm – 25mm |

| Length | 6m standard / Custom cut |

| Finish Options | Annealed, Pickled, Polished, Mirror, Brushed |

| Standard | ASTM A312 / A554 / EN / DIN / JIS |

* Custom bending, threading, flaring or perforation available on request.

Performance Characteristics and Applications of Stainless Steel Pipes

I. Performance Characteristics

Corrosion Resistance

The surface of stainless steel pipes forms a dense passivation film, effectively resisting corrosion from the atmosphere, water, and chemical media, maintaining stable appearance and performance over a long period. Its resistance to acid, alkali, and salt corrosion makes it particularly suitable for harsh environments such as chemical and petroleum industries.

High Temperature Resistance

It is not easily deformed, discolored, or oxidized in high-temperature environments and can withstand extreme temperature conditions (e.g., -270℃ to 400℃), making it suitable for high-temperature equipment such as boilers and heat exchangers.

Mechanical Properties

High tensile strength (>530N/mm), combined with toughness and ductility, enabling it to withstand high pressure and heavy loads, avoiding the risk of bursting or leakage.

Hygiene and Environmental Protection

The material is non-toxic and harmless, with a smooth inner wall that does not accumulate scale, eliminating secondary pollution and meeting drinking water standards; it is also 100% recyclable, reducing the environmental burden.

Aesthetics and Processability

The surface can be polished, brushed, or matte, offering a strong metallic texture and diverse shapes; excellent cold working and welding performance, facilitating stamping, bending, and other forming processes.

II. Main Applications

Architecture and Decoration

Civil Applications: Used in decorative projects such as stair railings, doors and windows, guardrails, and ceilings, enhancing the modern feel and structural strength of buildings.

Public Spaces: Widely used in interior and exterior decoration of shopping malls, hotels, and offices, such as furniture frames and artwork production.

Industrial Applications

Fluid Transportation: Used in the petrochemical and food industries to transport corrosive media, ensuring safe operation under high temperature and high pressure conditions.

Mechanical Construction: As a core component of boilers, heat exchangers, and piping systems, extending equipment lifespan.

Public Welfare Applications

Drinking Water Systems: Used as domestic water supply pipes, resistant to freezing and cracking, preventing bursts and ensuring water safety; service life can reach 100 years.

Bathroom Fixtures & Furniture: Used to manufacture bed frames, chairs, and bathroom fixtures, combining durability and a high-end feel.

Special Applications

Marine Engineering & Pharmaceuticals: Providing stable and reliable pipeline solutions in highly corrosive environments, such as offshore platforms and chemical plants.

Processing & Packaging

Pipe cutting, polishing, end-capping

Threading, grooving, or slotting

Mirror or brushed surface finish

Plastic caps + woven bag + steel frame bundle

Container loading with anti-scratch protection

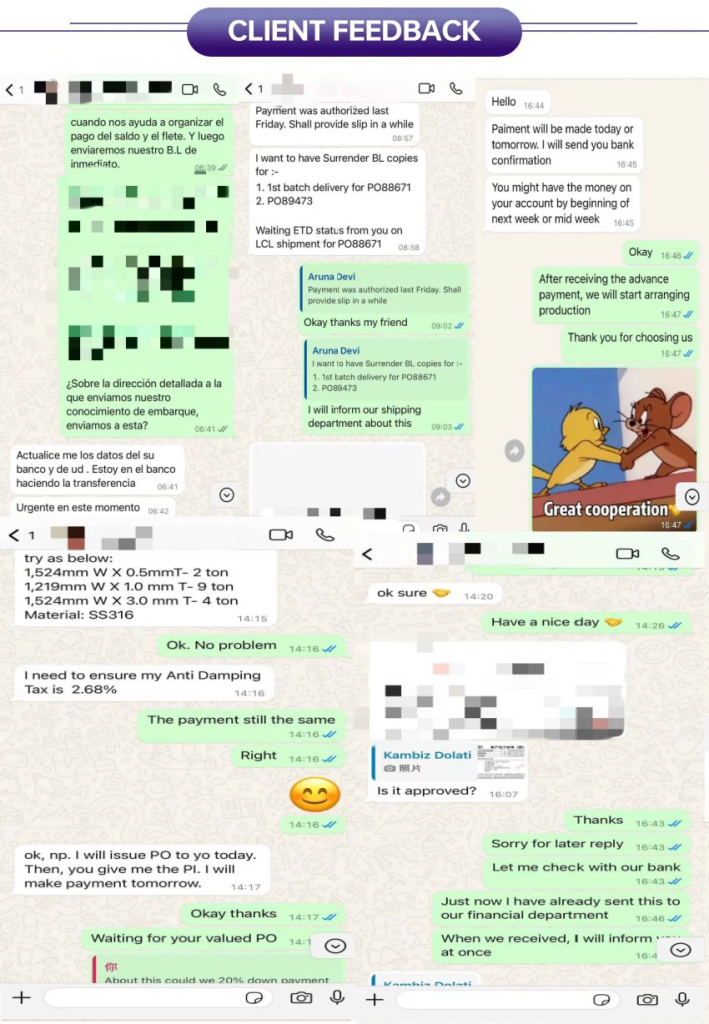

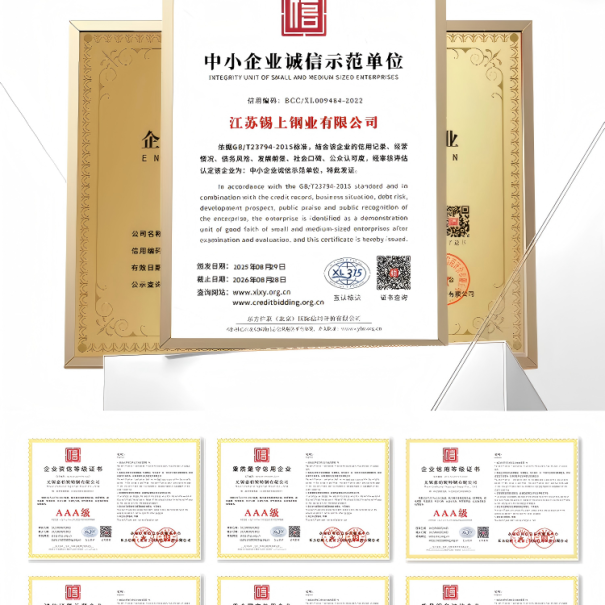

Why Buy From Xishang?

- Full grades of welded & seamless pipes in stock

- Cut-to-length, polish, thread, or perforate as needed

- SGS / ISO / MTC certification support

- Flexible MOQ starting from 1 ton

- Fast delivery via Shanghai, Ningbo, Tianjin ports

- One-stop sourcing with square, round, rectangular tubes available

Frequently Asked Questions

Q1: What’s the difference between seamless and welded pipes?

A:

Seamless pipes have no weld seam and are used for high-pressure and critical applications. Welded pipes are more economical and suitable for general use.

Q2: Do you offer decorative pipes with mirror finish?

A:

Yes. We supply tubes with mirror (8K), brushed (No.4), and hairline finishes for decorative applications.

Q3: Can stainless pipe be used outdoors?

A:

Yes. Grades like 304 and 316 are suitable for outdoor use, especially 316 for marine or coastal environments.

Q4: What is the tolerance for OD and wall thickness?

A:

Standard tolerance applies per ASTM A554 / A312, and tighter tolerances available upon request.

Q5: Can you do custom lengths or perforated tubes?

A:

Absolutely. We support CNC cutting, perforation, and slotting per customer drawings.