- You are here:

- Home /

- Products /

- Stainless Steel /

- Stainless Steel Bar

Stainless Steel Bar & Rod for Machining, Construction & More

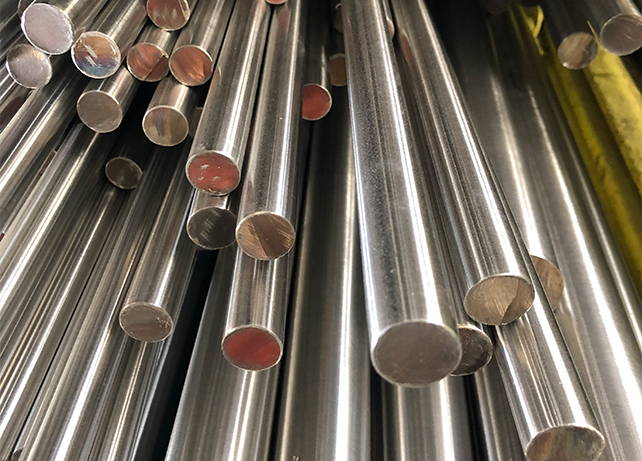

Precision-cut stainless steel bars in round, square, hex, and flat types. Full grades and sizes for mechanical, structural, and decorative use.

What Are Stainless Steel Bars & Rods?

Stainless steel bars and rods are solid steel profiles used for load-bearing, support, or precision machining. They offer exceptional strength, corrosion resistance, and machinability.

We offer:

Round bars – for shafts, pins, fasteners

Hexagonal bars – ideal for nuts, bolts, fittings

Square bars – for fabrication, structural supports

Flat bars – for brackets, supports, connectors

Available in hot rolled or cold drawn condition, and widely used in machinery, tooling, hardware, architecture, shipbuilding, and kitchen equipment.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Grades | 201, 304, 304L, 316, 316L, 410, 420, 430, 321 |

| Shapes | Round, Square, Hex, Flat |

| Diameter/Size | Round: 3mm–200mm, Flat: up to 100x10mm |

| Length | 1m–6m standard / Custom cut |

| Surface Finish | Annealed, Pickled, Bright, Black, Polished |

| Standard | ASTM A276, A479 / EN 10088 / JIS G4303 |

| Tolerance | h9/h11 or as requested |

* Support for centerless grinding, chamfering, and CNC cutting available.

A Comprehensive Analysis of the Performance Characteristics and Applications of Stainless Steel Bars

1. Core Performance Characteristics

1.1 Excellent Corrosion Resistance

A dense chromium oxide passivation film on the surface provides resistance to atmospheric and acidic/alkaline media corrosion, especially excellent performance against oxidizing acids (such as nitric acid with a concentration ≤65%) and organic acid environments.

1.2 Mechanical Property Advantages

Strength and Plasticity: Austenitic stainless steel (such as 304) has a tensile strength ≥520MPa and an elongation after fracture ≥40%, combining high toughness and machinability.

Temperature Adaptability: Withstands high temperatures up to 650℃ and maintains mechanical stability at low temperatures, suitable for operating conditions from -196℃ to 800℃.

1.3 Processing Characteristics

Outstanding hot working performance; no hardening during stamping and bending; excellent weldability, facilitating the manufacture of complex structures.

2. Main Application Areas

2.1 Consumer and Industrial Use

Household Products: Tableware, cabinets, boilers, and other food-grade contact applications, meeting hygiene and safety standards.

Architecture and Decoration: Railings, interior piping, and exterior wall decoration, balancing aesthetics and durability.

2.2 Industry and Technology

Chemicals and Energy: Heat exchangers, pipelines, and environmental protection equipment, resistant to high-pressure and corrosive environments.

Transportation and Machinery: Automobile mufflers and ship components, utilizing their impact resistance and salt spray resistance.

2.3 Medical and Special Scenarios

Medical Devices: Surgical instruments and implants, relying on biocompatibility and sterile surfaces.

Cutting-Edge Technology: Nuclear energy and aerospace fields, meeting high strength and radiation protection requirements.

3. Summary

Stainless steel bars, with their core advantages of corrosion resistance, high strength and toughness, and ease of processing, cover diverse scenarios from daily life to high-end technology, becoming an indispensable basic material for modern industry and people’s livelihood.

Applications

- CNC machining parts, shafts, and rods

- Structural framework and support systems

- Marine bolts, nuts, and anchors

- Furniture hardware and fixtures

- Railings and architectural components

- Industrial equipment frames

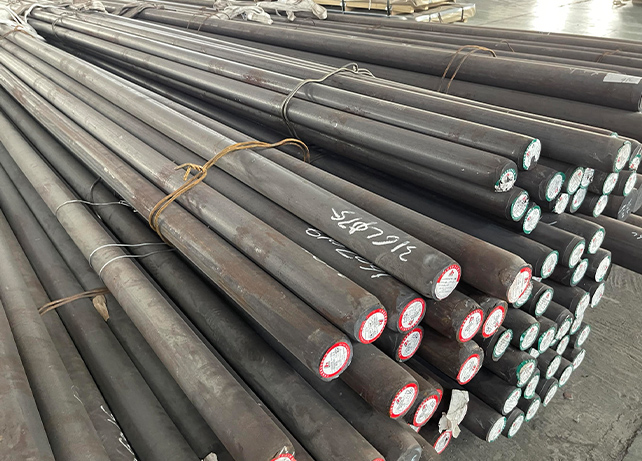

Processing & Packaging

Cutting, chamfering, polishing

Bright or mirror surface treatment

Oil-coated or dry finish

Bundled with steel strap + plastic wrap

Wooden crate or steel frame box as required

Why Buy From Xishang?

- Full inventory of 304 / 316L / 201 / 430 bar products

- Wide size range and cut-to-length service

- Machining-grade surface quality (bright or ground)

- Short lead time and custom processing

- All exports come with MTC & inspection options

- Support for small trial orders (MOQ 1 ton)

Frequently Asked Questions

Q1: What’s the difference between hot rolled and cold drawn bars?

A:

Cold drawn bars offer better surface finish, tighter tolerances, and higher strength. Hot rolled bars are more economical.

Q2: Can you supply precision ground bars for shafts?

A:

Yes. We offer centerless ground round bars with h9/h11 tolerance, suitable for high-precision shaft applications.

Q3: Do you have mirror polished flat bar?

A:

Yes. We can supply polished flat bars with mirror or brushed finish for decorative use.

Q4: Can you export hexagonal bars for bolt making?

A:

Certainly. Our hex bars are widely used in fastener and nut/bolt production.

Q5: What is your minimum order for stainless bars?

A:

MOQ is 1 ton per grade/size. Mixed sizes can be combined in one container.