- You are here:

- Home /

- Products /

- Stainless Steel /

- Stainless Steel Sheet /

- 309Si2 High-Temperature Austenitic Stainless Steel Plate

309Si2 High-Temperature Austenitic Stainless Steel Plate

A premium-grade material engineered for extreme thermal and corrosive environments, combining exceptional oxidation resistance with mechanical stability up to 800°C.

- High-Temperature Performance: Maintains structural integrity at 600–800°C with superior creep resistance.

- Oxidation/Nitridation Resistance: Chromium-rich oxide layer (19–22% Cr) ensures durability in aggressive atmospheres.

- Sensitivity Management: Optimized silicon content (1.5–2.5% Si) mitigates sulfur-induced corrosion while balancing ductility.

- Phase Stability: Controlled carbon (≤0.20% C) minimizes carbide precipitation during prolonged heat exposure.

Technical Parameters (Chemical Composition, wt%)

Physical Properties

- Density: 7.98 g/cm³

- Thermal Conductivity: 15.5 W/(m·K) at 100°C

- Linear Expansion: 16.5×10⁻⁶/K (0–100°C)

| Element | Range | Key Role | Si | Mn | P | S | Cr | Ni | N | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| C | ≤0.20 | Carbide control for weldability | - | 5.5 | - | - | 16 | 3.5 | - | 0.8 |

| 1.50–2.50 | Enhances oxidation resistance | 1 | 7.5 | 0.06 | 0.03 | 18 | 5.5 | 0.25 | 1.0 | |

| Mn | ≤1.50 | Deoxidizer, improves hot workability | - | 5.5 | - | - | 16 | 3.5 | - | - |

| ≤0.040 | Minimizes grain boundary weakness | 1 | 7.5 | 0.06 | 0.03 | 18 | 5.5 | 0.25 | 0.4 | |

| S | ≤0.030 | Limits hot shortness | - | 5.5 | - | - | 16 | 3.5 | - | 0.4 |

| 19.00–22.00 | Forms protective oxide scales | 1 | 7.5 | 0.06 | 0.03 | 18 | 5.5 | 0.25 | 0.8 | |

| Ni | 12.00–15.00 | Stabilizes austenitic structure | - | 5.5 | - | - | 16 | 3.5 | - | 1.0 |

| Maximum | 0.10 | 1 | 7.5 | 0.06 | 0.03 | 18 | 5.5 | 0.25 | 1.5 | |

| 201 J5 | Minimum | 0.14 | - | 5.5 | - | - | 16 | 3.5 | - | - |

| Maximum | 0.15 | 1 | 7.5 | 0.06 | 0.03 | 18 | 5.5 | 0.25 | 0.4 |

309Si2 stainless steel plate is a high-alloy austenitic stainless steel. Its performance characteristics and applications are as follows:

Performance Characteristics

1.1 High Temperature Resistance: 309Si2 stainless steel plate can be repeatedly heated in high-temperature environments up to 980℃ without significant performance degradation, exhibiting extremely high high-temperature strength and stability. This is due to its high chromium and nickel content, effectively resisting high-temperature oxidation reactions and extending its service life.

1.2 Oxidation and Corrosion Resistance: Containing a high proportion of chromium and nickel, it forms a dense oxide film, maintaining excellent corrosion resistance in strong acids, strong alkalis, and high-concentration salt solutions, protecting equipment from corrosion.

1.3 Good Machining Performance: Possessing high plasticity and weldability, it is easily processed into complex shapes through laser cutting, rolling, and other processes to meet diverse industrial needs.

Applications

2.1 High-Temperature Industrial Equipment: Widely used in heat treatment equipment, oil refining furnaces, and other high-temperature working environments, its heat resistance and stability make it an ideal material.

2.2 Chemical and Petroleum Industries: Used in the manufacture of reaction vessels, storage tanks, and pipelines, providing reliable protection in corrosive media, suitable for the chemical and petroleum industries.

2.3 Power and Machinery Manufacturing: Plays a critical role in power equipment such as boilers and mechanical components, ensuring structural integrity and durability under high-temperature conditions.

309Si2 stainless steel plate, with its superior performance, has become the material of choice for high-temperature and corrosive environments, supporting the stable operation of multiple industrial sectors.

Surface Finishes

- Pickling & Passivation:

- Removes scale, enhances Cr-oxide layer.

- Electropolishing:

- Reduces surface roughness (Ra ≤0.8μm) for hygienic applications.

- Shot Blasting:

- Prepares surfaces for high-temperature coatings.

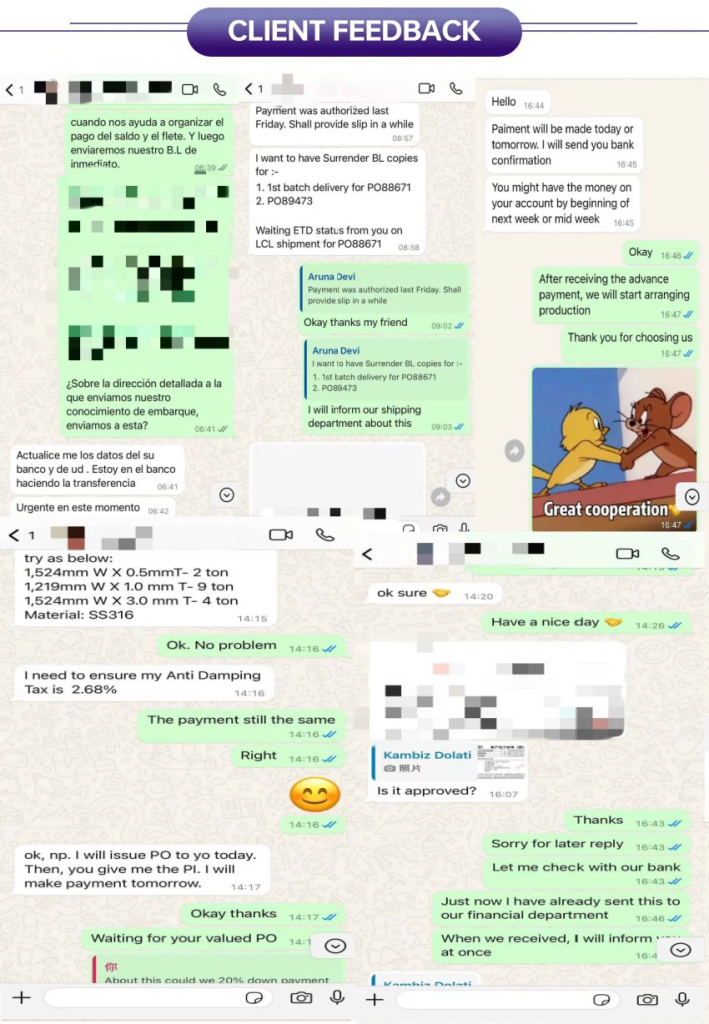

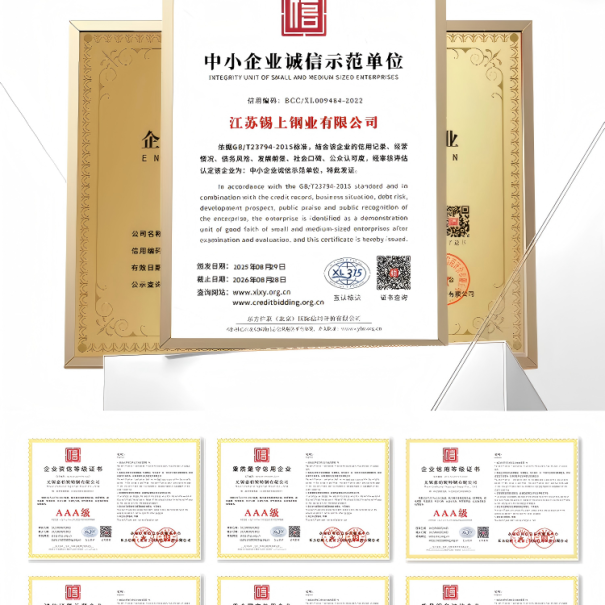

Why Choose Us ?

- Certified Quality: Compliant with GB/T 4237, EN 10095, and JIS G4303.

- Precision Processing: Laser-cut tolerances ±0.1mm, tailored annealing at 1080–1130°C.

- Global Logistics: 72-hour dispatch with moisture-proof packaging.

Applications & Industries

Thermal Processing

Furnace rolls, radiant tubes, burner liners

Food Processing

Baking conveyors, high-temperature ovens

Power Generation

Boiler parts, flue gas systems

Petrochemical

Cracking furnace tubes, heat exchangers

Automotive

Exhaust systems, turbo housing components

Workshop & Packaging (Illustrative)

- Production Workshop:

- Automated rolling mills with real-time thickness monitoring.

- Packaging Standards:

- VCI-coated steel strapping on wooden pallets (IPPC-certified).

Frequently Asked Questions

Q1: How to avoid 600–800°C embrittlement?

A: Limit dwell time in this range; post-weld anneal at 1100°C for critical applications.

Q2: Compatible welding methods?

A: TIG with ER309L filler (98% Ar + 2% N₂ shield gas).

Q3: What distinguishes 309Si2 from 304/316 stainless steel?

A: 309Si2 offers superior high-temperature performance (up to 1150°C vs. 870°C for 304/316) and enhanced oxidation resistance due to its higher silicon content.

Q4: Can 309Si2 be used in reducing atmospheres?

A: No, it is designed for oxidizing environments. For reducing conditions, consider alloys like 310S or 330.

Q5: How does 309Si2 perform in cyclic thermal conditions?

A: Exhibits excellent thermal fatigue resistance due to its stable oxide layer and low thermal expansion coefficient.

Ready to source stainless steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.