- You are here:

- Home /

- Products /

- Carbon Steel /

- Carbon Steel Structural Profiles

Carbon Steel Structural Profiles – Strong, Reliable & Widely Used

We supply carbon steel angle, channel, and beam profiles in various sizes and standards. Perfect for framing, support, mechanical use, and construction infrastructure.

What Are Carbon Steel Structural Profiles?

Carbon steel structural profiles are long steel bars with defined cross-sections used for structural reinforcement, framework, and load-bearing purposes in construction and engineering.

We supply the following profiles:

Angle Steel (L-bar): for brackets, frames, and supports

Channel Steel (U/C-bar): for beams, trailers, machinery frames

I-Beam / H-Beam: for large-scale construction and bridges

T-Bar / Z-Bar / C-Purlin: on request.

They offer excellent mechanical strength, weldability, and cost-efficiency.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Grades | Q195, Q235, Q345, SS400, A36, S235JR, S355JR |

| Angle Bar Size | 20x20 – 200x200mm / Thickness: 3 – 20mm |

| Channel Size | 50x25 – 300x90mm (U/C) / Thickness: 3 – 16mm |

| I-Beam / H-Beam | Web Height: 100 – 600mm / Flange Width: 50 – 300mm |

| Length | 6m, 9m, 12m, or customized |

| Finish | Black, painted, galvanized (on request) |

| Standard | ASTM A36 / JIS G3101 / EN 10025 / GB 9787 |

* Also support drilling holes, welding brackets, and cutting to size.

Analysis of Performance Characteristics and Applications of Carbon Steel Profiles

1. Performance Characteristics

1.1 Mechanical Properties

Low-carbon steel (carbon content ≤ 0.25%) has excellent plasticity and toughness, making it easy to stamp and weld, but its strength is relatively low.

Medium-carbon steel (carbon content 0.25%-0.6%), after quenching and tempering, exhibits significantly improved strength and toughness, making it suitable for bearing larger loads.

High-carbon steel (carbon content > 0.6%) has high hardness and strong wear resistance, but poor plasticity and toughness, and is prone to brittleness.

1.2 Processing Properties

Low-carbon steel has good cold formability, suitable for stamping, bending, and other processing; medium and high-carbon steels require heat treatment to optimize performance.

Weldability decreases with increasing carbon content; low-carbon steel is easy to weld, while high-carbon steel requires special processes.

1.3 Environmental Adaptability

Poor corrosion resistance, prone to rust, requiring surface treatment (such as galvanizing) to extend service life.

Performance degrades significantly under high or low temperatures, making it unsuitable for extreme temperature scenarios.

2. Main Applications

2.1 Construction and Infrastructure

Low-carbon steel is used to manufacture reinforcing bars, bolts, rivets, etc. Due to its low cost and good plasticity, it is suitable for large-scale projects.

Medium-carbon steel is used in bridge frames and building support structures. After quenching and tempering, it can withstand dynamic loads.

2.2 Machinery Manufacturing

Medium-carbon steel is widely used in shafts, gears, connecting rods, and other parts. Quenching and tempering can balance strength and toughness.

High-carbon steel is used in wear-resistant parts such as cutting tools, molds, and springs. Surface hardening significantly increases its hardness.

2.3 Industrial Tools and Equipment

Low-carbon steel stampings are used in automotive shells and electronic device frames, suitable for machining complex shapes.

High-carbon steel cutting tools (such as drill bits and reamers) have high hardness and are suitable for precision machining.

3. Application Advantages and Limitations

Advantages: Low cost, easy to process, and adjustable strength; it is the “king of cost-effectiveness” in the industrial field.

Limitations: It has poor corrosion resistance and requires protective measures; high-carbon steel is brittle and not suitable for high-impact scenarios.

Processing & Packaging

Saw cutting to fixed lengths

Rust-prevention painting or galvanization

Bundled by steel strip and labeled

PE wrap, wood skid, or palletized packaging

Steel structure loading plan optimization

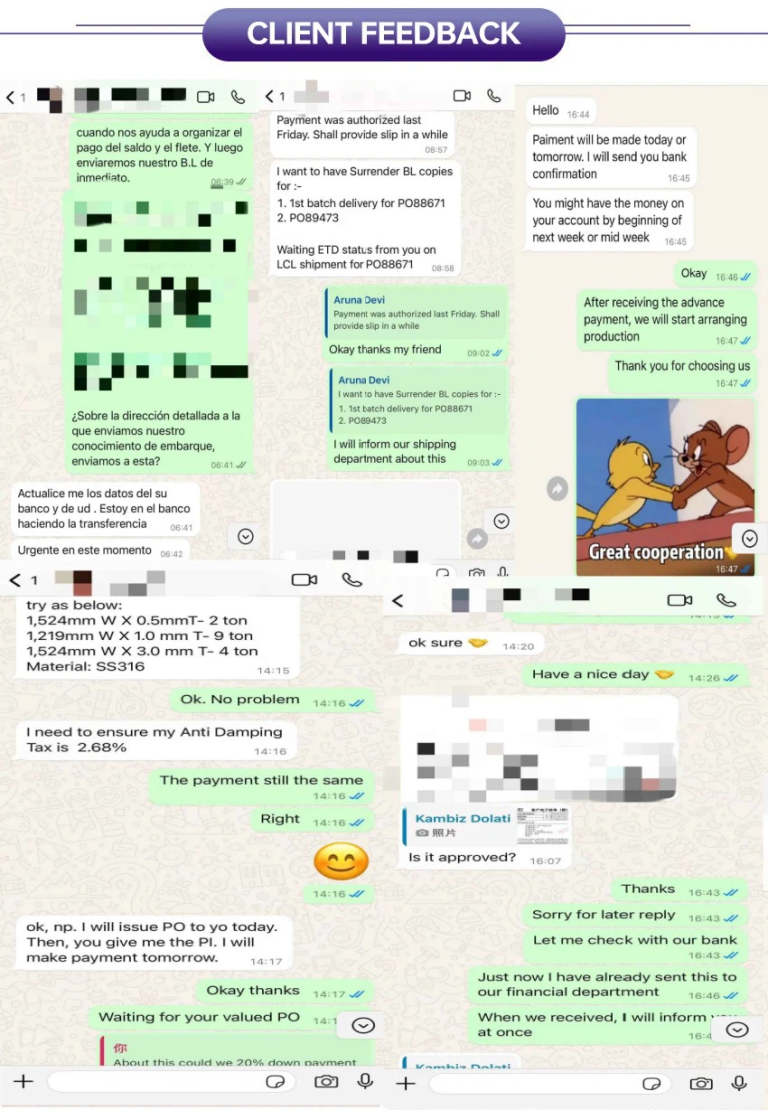

Why Choose Xishang?

- Full range of structural profiles in all sizes

- Flexible MOQ with mixed type & size loading

- Custom cutting and punching supported

- Export-standard surface treatment

- Fast lead time for construction projects

- Technical support with drawings and standards

Frequently Asked Questions

Q1: What’s the main use of angle steel in construction?

A:

Angle steel is often used as corner bracing, framing support, and structural reinforcement due to its L-shape design.

Q2: Can you cut to custom lengths like 7.5m or 9.3m?

A:

Yes. We provide custom-length cutting as per your requirement.

Q3: Do you offer hot-dip galvanized angle or channel?

A:

Yes. Galvanized structural profiles are available for corrosion resistance.

Q4: What's the difference between I-beam and H-beam?

A:

I-beams have narrower flanges; H-beams are heavier with wider flanges for higher load capacity.

Q5: Are these profiles suitable for export projects?

A:

Absolutely. All profiles are export-packaged and can be used in major global construction standards.

Whether for steel warehouse structure, frame construction or machinery support.