- You are here:

- Home /

- Products /

- Carbon Steel /

- Carbon Steel Sheet/Plate

High Strength Carbon Steel Plate for Structural and Industrial Use

Carbon steel plates in a wide range of grades and thicknesses. Suitable for bridges, machinery, pressure vessels, shipbuilding, and more. Available in cut-to-size, with fast delivery.

What Is Carbon Steel Plate?

Carbon steel plate is a flat steel sheet made from carbon-rich alloy with superior mechanical strength and cost-effectiveness. It is widely used in structural fabrication, machine parts, automotive frames, pressure vessels, and shipbuilding.

We supply carbon steel plates in:

- Mild Steel (Low Carbon)– Easy to cut, weld, and shape

- Medium/High Carbon– Better hardness and strength

- Boiler & Pressure Vessel Grade– Excellent toughness

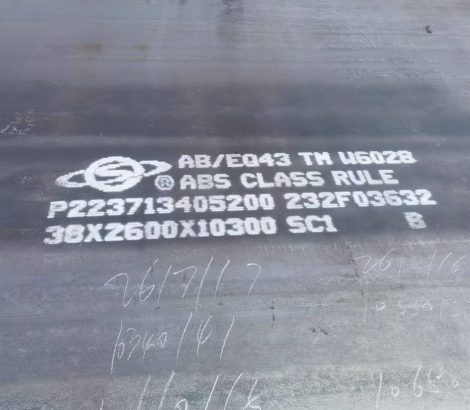

- Shipbuilding Grade– High tensile, seawater-resistantAbrasion-Resistant Plate– For mining and construction

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Steel Grades | Q195, Q235, Q345, 45#,1040,1060,A36, SS400, S235JR, S355JR, ASTM A516, A572, A588,NM400,NM450,NM600 |

| Thickness | 0.5mm – 300mm |

| Width | 60mm – 2500mm |

| Length | 1000mm – 12000mm or as required |

| Standards | ASTM / EN / JIS / GB / DIN |

| Surface Finish | Mill finish, pickled, sandblasted, or coated |

| Heat Treatment | As-rolled, Normalized, Quenched & Tempered (Q+T) |

* Support plasma cutting, beveling, drilling, and edge trimming.

Performance Characteristics and Core Application Areas of Carbon Steel Plates

1. Performance Characteristics

1.1 Mechanical Properties

Strength and Hardness: Carbon content directly affects performance. Low-carbon steel (≤0.25%) has good plasticity and high toughness, suitable for cold working; medium-carbon steel (0.25%-0.60%) has moderate strength, and its overall performance can be improved through heat treatment; high-carbon steel (>0.60%) has high hardness and strong wear resistance, but lower plasticity and toughness.

Processing Performance: Low-carbon steel is easy to weld and stamp, while high-carbon steel requires special treatment (such as quenching and tempering) to reduce brittleness.

1.2 Environmental Adaptability

Corrosion Resistance: Carbon steel is easily oxidized and requires enhanced protection through galvanizing, painting, or alloying (such as weathering steel), especially in humid environments.

Temperature Resistance: The upper limit of long-term operating temperature for ordinary carbon steel is approximately 350°C. For high-temperature environments, heat-resistant steel must be used.

1.3 Economic Efficiency

Low cost, approximately one-third the price of stainless steel, suitable for large-scale production, making it the “king of cost-effectiveness” in industrial materials.

2. Main Applications

2.1 Building Engineering

Structural Support: Low-carbon steel (e.g., Q235B) is used for factory frames and bridge main beams, balancing strength and cost; high-strength steel (e.g., HC340LA) is used for weight reduction in high-rise buildings.

Enclosure Systems: Galvanized carbon steel sheets (e.g., DX51D) are used for roofing and wall panels, improving rust resistance.

2.2 Machinery Manufacturing

Transmission Components: Medium-carbon steel (e.g., 45#) is heat-treated to manufacture gears and shafts, balancing strength and toughness.

Equipment Housings: Cold-rolled steel sheets (e.g., SPCC) are used for machine tool protective covers, with a surface coating to prevent oil stains.

2.3 Automotive Industry

Body Structure: Low-carbon steel sheets (such as DC04) are used for doors and hoods to achieve lightweighting and impact energy absorption; high-strength steel is used for chassis components to increase strength and reduce weight.

2.4 Shipbuilding and Energy

Ship Construction: Marine carbon steel (such as AH36) passes low-temperature impact testing to ensure safety during polar navigation.

Energy Pipelines: Pipeline steel (such as API5L Gr.B) is used for oil and gas transportation, with a yield strength ≥245 MPa.

3. Future Trends

With the development of green buildings, carbon steel sheets are increasingly used in energy-saving projects, such as negative carbon demonstration buildings that use high-performance envelope systems combined with photovoltaic technology to improve energy efficiency.

The above content summarizes the core characteristics and diverse applications of carbon steel sheets, providing a reference for material selection and design.

Processing & Packaging

CNC cutting (plasma / flame) to shape

Blasting and painting (if needed)

Beveling and chamfering

PE wrap + steel pallet or crate

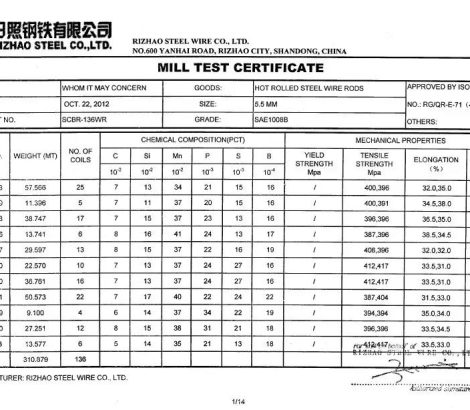

Mill Test Certificate (MTC) included

Why Choose Xishang?

- Large inventory of standard and specialty carbon plates

- Full range of thickness, width, and hardness

- Custom CNC cutting and drilling available

- Fast lead time with export packaging

- One-stop sourcing for structural and pressure grades

- Compliance with ISO/SGS/BV standards

Frequently Asked Questions

Q1: What is the difference between mild steel and structural plate?

Mild steel is low carbon and easily formable; structural plates like Q345 or S355 have higher strength and are used in load-bearing applications.

Q2: Do you supply boiler-grade carbon steel plate?

Yes. We offer ASTM A516, Q245R, and related grades suitable for pressure vessels and tanks.

Q3: Can you cut the plate into parts or flanges?

Absolutely. We support precision plasma cutting to custom drawings.

Q4: What are your available thicknesses?

We stock from 2mm thin sheets to 300mm heavy plates.

Q5: Is carbon steel plate suitable for outdoor environments?

Yes, especially grades like A588 or painted surfaces for weather resistance.