- You are here:

- Home /

- Products /

- Carbon Steel /

- Carbon Steel Coil

Carbon Steel Coils – Strong, Versatile & Ready for Processing

We supply carbon steel coils in both hot rolled and cold rolled finishes, suitable for pipe manufacturing, stamping, structural parts and more. Slit-to-width and custom coil services available.

What Is Carbon Steel Coil?

Carbon steel coil is a rolled form of steel sheet used as a raw material for fabricating flat or tubular steel components. It’s an ideal choice for industries that require strong, economical, formable steel.

Types of Coils Supplied:

Hot Rolled Coil (HRC): Lower cost, scaled surface, used in construction and welding

Cold Rolled Coil (CRC): Smooth finish, tighter tolerances, used in automotive, appliances

Pickled & Oiled Coil (P&O): Surface cleaned and oiled to prevent rust during storage

Available in full width coils, or slit to custom sizes, depending on downstream processing needs.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Steel Grades | Q195, Q235, Q345, A36,SS400,S235JR,A106Gr.B,45#, SPHC,SPCC,ST12, DC01,DC04,65Mn |

| Thickness | 0.5mm – 80mm |

| Width | 60mm – 2500mm |

| Coil ID / OD | ID: 508mm / 610mm, OD: up to 2000mm |

| Edge Options | Mill edge / Slit edge |

| Surface Finish | Black (as rolled), Pickled & Oiled, Bright (cold rolled) |

| Standard | ASTM A1011 / EN 10025 / JIS G3131 / GB/T 700 |

* Support for slitting, edge trimming, oiling, cut-to-length sheet production.

Performance Characteristics and Applications of Carbon Steel Coils

1. Performance Characteristics

1.1 Mechanical Properties

The strength and hardness of carbon steel coils are mainly determined by their carbon content. Low-carbon steel (carbon content <0.25%) has excellent plasticity and weldability. Medium-carbon steel (0.25%-0.55%) can significantly improve strength and toughness after quenching and tempering. High-carbon steel (>0.6%) has high hardness but poor plasticity. Its hardenability is low, making it difficult to obtain uniform mechanical properties for large-section parts.

1.2 Machining Performance

Low-carbon steel is easy to stamp and hot/cold work, suitable for manufacturing complex-shaped stamped parts. Medium-carbon steel can have its wear resistance enhanced through surface quenching. High-carbon steel has good elasticity after quenching and medium-temperature tempering, but is prone to quenching deformation.

1.3 Environmental Adaptability

The performance of carbon steel coils decreases significantly at high or low temperatures, and its corrosion resistance is poor, requiring improvement through plating or coating.

2. Main Applications

2.1 Automotive Manufacturing

Low-carbon steel coils are used in body panels and stamped parts (such as doors and hoods) to achieve lightweighting and improve collision safety; medium-carbon steel coils are used in chassis components (such as suspension systems), and special coating treatments can extend their corrosion resistance life.

2.2 Construction and Engineering

Medium-carbon steel coils are used in steel structure frames, bridge supports, etc., due to their excellent seismic performance and ability to withstand large loads.

2.3 Home Appliances and Consumer Goods

Low-carbon steel coils are used in refrigerator side panels, washing machine drums, etc., combining corrosion resistance and ease of processing.

2.4 Tools and Machine Parts

High-carbon steel coils are used to manufacture springs (such as valve springs and leaf springs) and cutting tools; their high hardness and wear resistance meet high strength requirements.

2.5 Precision Instruments

Some high-precision carbon steel coils are used in medical devices and aerospace components, requiring surface treatment processes to improve performance.

Processing & Packaging

Coil slitting to customer width (e.g. 300mm, 914mm, 1219mm)

Cut-to-length sheet line

Surface galvanizing to reduce rust

PE wrap + steel strapping + edge guards

Palletized or eye-to-wall container loading

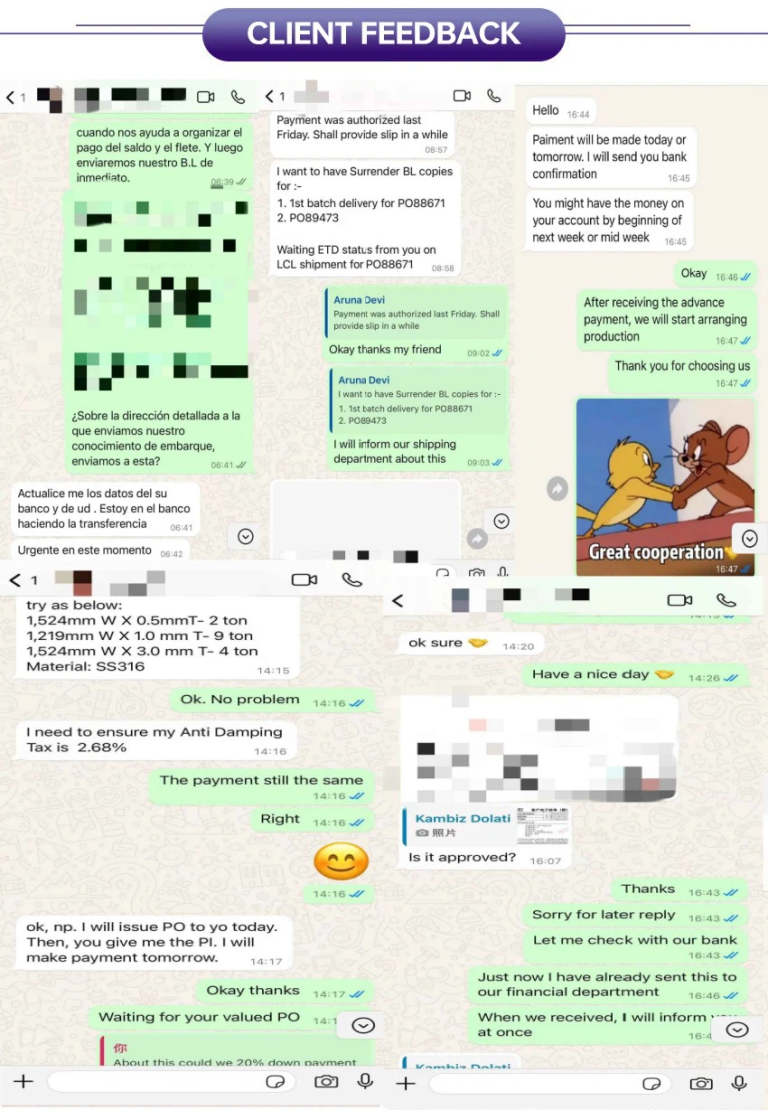

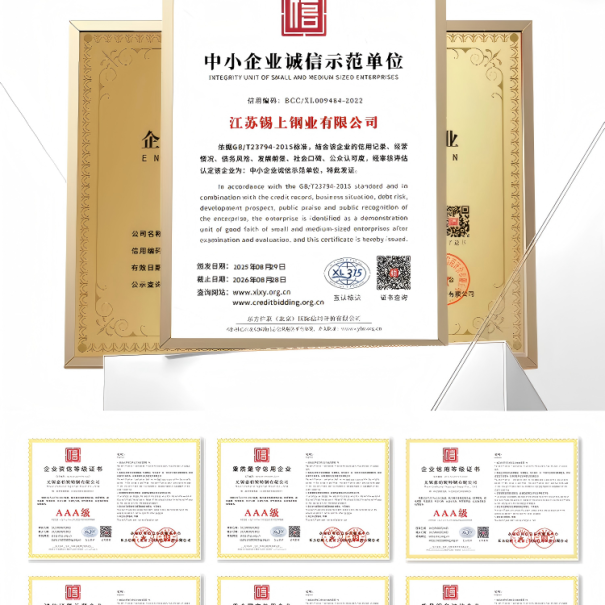

Why Choose Xishang?

- Hot and cold rolled coils in full thickness range

- Edge slitting & precision width tolerance

- Available in pickled, dry, or oiled condition

- MOQ flexible for both stock and production

- Fast coil dispatch with export-grade packaging

- Competitive factory pricing + mill certificate support

Frequently Asked Questions

Q1: What’s the difference between hot and cold rolled carbon coils?

A:

Hot rolled coils are cheaper, rougher surface, used in structural work. Cold rolled coils have tighter tolerances and better surface finish.

Q2: Do you offer slit coils or narrow width?

A:

Yes, we can slit to any width (e.g. 100mm, 914mm) and bundle separately.

Q3: What’s the minimum order for carbon steel coil?

A:

Our MOQ starts from 3 tons per size. Trial orders are welcome.

Q4: Can you provide oil-coated surface to prevent rust?

A:

Yes. We offer oiling service for HRC, CRC and pickled coils.

Q5: What are your standard packaging methods?

A:

Plastic film wrap, edge protector, steel band, waterproof paper, eye-to-wall or eye-to-sky packing.