- You are here:

- Home /

- Products /

- Carbon Steel /

- Carbon Steel Bar

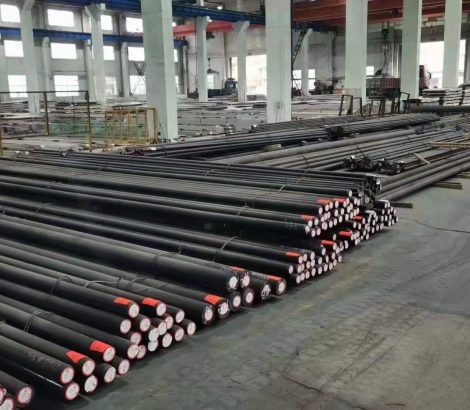

Carbon Steel Rod & Bar – Precision, Strength & Reliable Supply

We offer round, square, flat and hex carbon steel bars in multiple grades and finishes. Ideal for machining, construction, automotive, tool making, and general fabrication.

What Are Carbon Steel Rods & Bars?

Carbon steel bars are long, solid metal products used for machining, reinforcement, tool making, and component manufacturing. Depending on shape and finish, they serve various mechanical and industrial needs.

We provide:

- Round Bars– for shafts, pins, fasteners, hardware

- Flat Bars– for frames, brackets, plates

- Square Bars– for fabrication, railings, joints

- Hexagonal Bars– for bolts, nuts, CNC machining

- Cold Drawn Bars– better tolerance & surface

- Hot Rolled Bars– cost-efficient for general use

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Steel Grades | Q195, Q235, Q345,Q345, A36, S235JR, 45#, C45,SAE1010, SAE1045,65#、70#、65Mn,SWRH62A,SWRH72A,82B,DIN17223-A,60Si2MnA |

| Diameter | 0.5mm – 2000mm (round bar) |

| Width/Thickness | Flat bar: 12mm – 300mm width, 2mm – 100mm thick |

| Length | 3m, 6m, 9m, 12m or custom |

| Surface | Black, pickled, peeled, bright (CD) |

| Tolerances | h9 – h13 / As per drawing |

| Standard | ASTM A36 / EN 10025 / JIS G3101 / GB/T 702 |

* Custom cut lengths, chamfered ends, and bundling available.

Performance Characteristics and Applications of Carbon Steel Bars

1. Performance Characteristics of Carbon Steel Bars

The performance of carbon steel bars mainly depends on their carbon content. They can be divided into three categories: low-carbon steel, medium-carbon steel, and high-carbon steel, each with significant differences.

1.1 Low-carbon steel (carbon content ≤ 0.25%)

Performance characteristics: Low hardness, good plasticity, high toughness, excellent weldability, strong cold and hot working formability, but relatively low strength.

Typical applications: Automotive body steel plates, pipe steel, building reinforcement bars, ordinary bolts and nuts, stamped parts (such as appliance housings), etc.

1.2 Medium-carbon steel (carbon content 0.25%~0.60%)

Performance characteristics: Higher strength and hardness than low-carbon steel, lower plasticity and toughness, comprehensive mechanical properties can be significantly improved through heat treatment (such as quenching and tempering), moderate weldability.

Typical applications: Shaft parts in mechanical manufacturing (such as motor shafts), gears, connecting rods, crankshafts, cutting tools (non-high-speed cutting), etc.

1.3 High-carbon steel (carbon content > 0.60%)

Performance characteristics: High hardness, high strength, excellent wear resistance, but poor plasticity and toughness, poor weldability, and prone to rusting. Heat treatment (e.g., quenching + low-temperature tempering) is usually required to further improve performance.

Typical applications: Cutting tools (e.g., hand saw blades, files), molds (e.g., cold stamping dies), springs (e.g., automotive shock absorber springs), wire ropes, etc.

2. General performance advantages of carbon steel bars

Strength and hardness: Increasing carbon content significantly improves hardness and strength, but excessive carbon content reduces plasticity and toughness.

Wear resistance and corrosion resistance: High-carbon steel has outstanding wear resistance, but its overall corrosion resistance is relatively weak, requiring protective treatment.

Cost and processing: Inexpensive, simple forming and heat treatment processes, suitable for large-scale applications.

3. Typical uses of carbon steel bars

Construction and engineering: Low-carbon steel is used for structural components in factories, bridges, and ships; medium-carbon steel is used for mechanical parts subjected to heavy loads.

Mechanical Manufacturing: High-carbon steel is used for tools, molds, and measuring instruments; medium-carbon steel is used for gears and shaft parts.

Everyday Life: Kitchen utensils, knives, building materials, etc., due to their strength, durability, and low cost.

Automotive Industry: Low-carbon steel is used for body and engine parts; lightweight design improves fuel efficiency.

Carbon steel bars, with their diverse performance characteristics and wide range of applications, have become an indispensable material in industrial production and daily life.

Processing & Packaging

Cut-to-length and fixed length service

Polishing, chamfering, or deburring

Painted, oiled, or rust-prevented bars

Bundled by weight or piece count

Export packaging with PE wrap + steel strip + wooden cradle

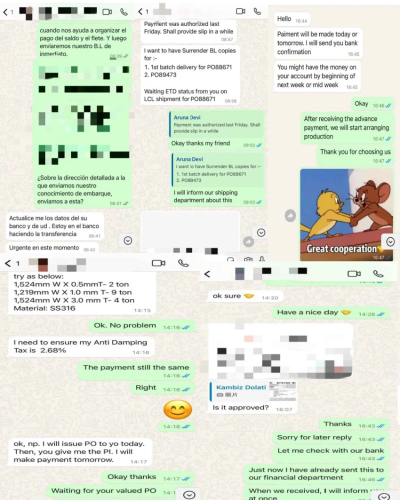

Why Choose Xishang?

- Wide range of shapes and sizes in stock

- Hot rolled & cold drawn finishes available

- Full machining and cutting support

- Surface polishing, chamfering, marking services

- Export packaging and small quantity ready

- Mill certificate and third-party test support

Frequently Asked Questions

Q1: What’s the difference between hot rolled and cold drawn bar?

A:

Hot rolled bars are cheaper and rougher; cold drawn bars have tighter tolerances and smooth finish, ideal for machining.

Q2: Can I buy cut-to-length bars for CNC use?

A:

Yes. We offer precision cutting service for round or square bars.

Q3: Do you provide bright round bar?

A:

Yes, we offer bright drawn bars with polished surface and precise tolerance.

Q4: What shapes are available besides round?

A:

Flat bar, square bar, hex bar, and customized profiles can be produced.

Q5: Do you have non-standard sizes or special grades?

A:

Yes, contact us with your drawing or sample for tailored production.