- You are here:

- Home /

- Products /

- Aluminmu Steel /

- Aluminum Steel Sheet/Plate

Aluminum Sheets & Plates – Lightweight, Durable, and Versatile

Available in a wide range of thicknesses and grades for construction, automotive, signage, electronics, and precision machining. Slitting, surface finishing and CNC cutting supported.

What Are Aluminum Sheets & Plates?

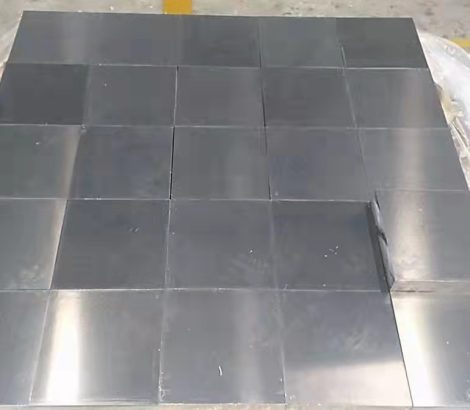

Aluminum sheet and plate are flat-rolled products made from pure aluminum or alloyed aluminum. Sheets are typically thinner (<6mm), while plates are thicker and used in structural or industrial settings.

Key Features:Lightweight & corrosion resistant、Excellent thermal & electrical conductivity、Non-magnetic and recyclable、Available in decorative & technical finishes

Commonly supplied in:

Mill finish、Brushed or polished、Anodized (color or clear)、Embossed (e.g. 5-bar tread plate)

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Alloy Grades | 1050, 1060, 1100, 3003, 3105, 5005, 5052, 5754, 6061, 6063, 7075 |

| Thickness | 0.2mm – 150mm |

| Width | Up to 2000mm |

| Length | Up to 6000mm or custom |

| Temper | H14, H24, H32, O, T6, T651 |

| Surface Finish | Mill, anodized, embossed, powder-coated, brushed |

| Standard | ASTM B209, EN573, JIS H4000, GB/T 3880 |

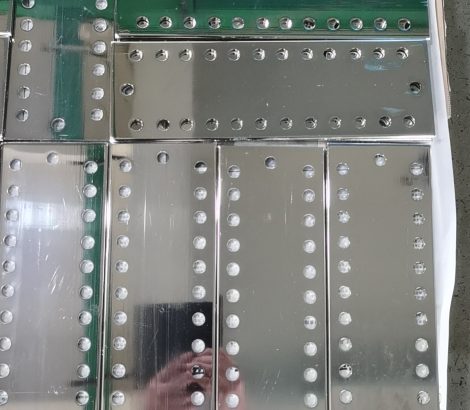

* Custom cutting, protective film lamination, and CNC punching available.

Performance Characteristics and Applications of Aluminum Sheets

I. Performance Characteristics

1. Lightweight and High Strength: Aluminum sheets have a density approximately one-third that of steel. Alloying significantly enhances their strength, resulting in a lightweight yet high load-bearing capacity, making them suitable for weight-sensitive structural designs.

2. Excellent Corrosion Resistance: An oxide film easily forms on the surface, effectively resisting corrosion from the atmosphere, humid environments, and chemicals, extending service life and reducing maintenance costs.

3. Excellent Thermal and Electrical Conductivity: As a highly efficient thermal and electrical conductor, aluminum sheets are widely used in heat dissipation systems, electronic equipment, and power transmission, improving energy efficiency and reliability.

4. Excellent Processing Performance: Easy to cut, bend, weld, and form, with high plasticity, supporting customized complex geometries to meet diverse design needs.

5. Environmental Protection and Recyclability: Aluminum sheets are 100% recyclable, with a high residual value, conforming to sustainable development principles and reducing resource waste and environmental pollution.

II. Main Applications

1. Construction

Curtain Walls and Decoration: Aluminum panels are used in building exterior walls, beams, columns, canopies, etc., offering lightweight construction, weather resistance, and a wide range of colors to enhance architectural aesthetics.

Interior Applications: Such as ceilings and partitions, utilizing their easy-to-clean and fire-resistant properties to optimize spatial functionality and safety.

2. Transportation

Automotive and High-Speed Rail: Used in body panels, interior trim, and sound barriers to reduce weight and enhance corrosion resistance, improving fuel efficiency and passenger comfort.

Subways and Aviation: Lightweight design reduces energy consumption while meeting high strength and durability requirements.

3. Electronics and Appliances

Radiators and Housings: Utilizing their thermal conductivity, they are widely used in heat dissipation components and housings for electronic devices such as mobile phones and computers, ensuring stable equipment operation.

Power Transmission: As a conductive material, used in busbars, cables, etc., to improve power transmission efficiency and reliability.

4. Home Furnishings and Consumer Goods

Kitchen Equipment: Such as cabinet panels and appliance housings, scratch-resistant and easy to clean, improving product durability and user experience. Daily-use hardware: Including furniture, lighting fixtures, etc., combining aesthetics and functionality to meet the needs of modern life.

5. Industry and Packaging

Machinery manufacturing: Used for molds and structural components, supporting high-precision machining and complex processes.

Packaging materials: Lightweight and moisture-proof, suitable for food, pharmaceutical, and other packaging, ensuring product safety and efficient transportation.

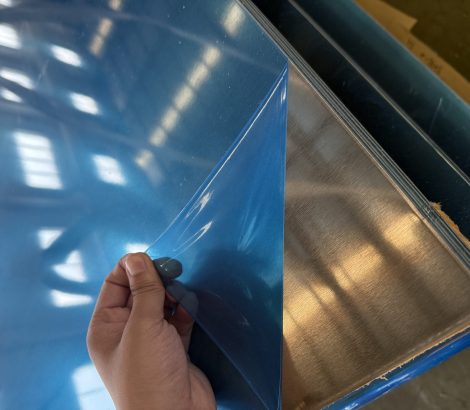

Processing & Packaging

Slitting, shearing, leveling, and deburring

One-side or double-side PE protective film

Laser cutting or punching by drawing

Standard seaworthy wooden pallet + moisture protection

Bundle ID/label + barcoding as per customer request

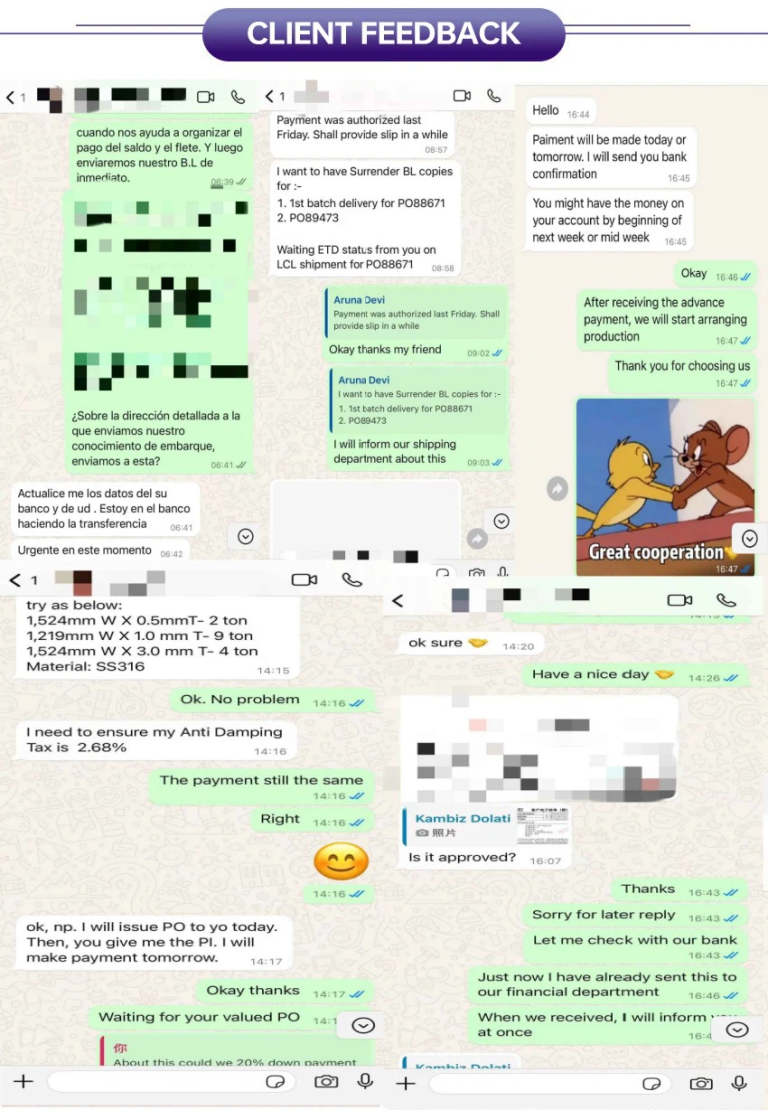

Why Choose Xishang?

- Full inventory of pure and alloy aluminum grades

- Anodizing, brushing, coating and embossing services

- Precision tolerance cutting and CNC shaping

- Low MOQ and flexible mixed grade orders

- Export-grade packaging and protective film wrapping

- SGS/BV/ISO certification with full MTC available

Frequently Asked Questions

Q1: What is the difference between aluminum sheet and plate?

A:

Sheets are typically under 6mm thick, used for cladding, signage, or decoration. Plates are 6mm+ and used for machining, molds, and structural purposes.

Q2: Which grade is best for corrosion resistance?

A:

5052 and 5754 offer excellent corrosion resistance, especially in marine and industrial environments.

Q3: Do you provide colored anodized or brushed aluminum sheets?

A:

Yes. We offer various surface treatments including brushed, colored anodizing, mirror, and matte finishes.

Q4: Can I order small quantities for trial?

A:

Absolutely. Our MOQ starts at 1 ton per grade and we support mixed-spec orders.

Q5: Is customized size and edge trimming available?

A:

Yes. We can cut to any specific width/length and deburr or polish edges as needed.