- You are here:

- Home /

- Products /

- Aluminmu Steel /

- Aluminum Steel Pipe/Tube

Aluminum Pipes & Tubes – Lightweight, Corrosion-Resistant, Precision Engineered

We supply round, square, and rectangular aluminum tubes for structural framing, automation, heat exchangers, transportation, and decoration. Wide range of alloys and finishes available.

What Are Aluminum Pipes & Tubes?

Aluminum pipes and tubes are hollow extrusions or drawn products used for both structural and fluid applications. Thanks to their lightweight, rust-resistance, and formability, they are popular in a wide variety of industries.

Common Shapes & Uses:

Round Tube / Pipe – for fluid transport, frames, marine, furniture

Square Tube – ideal for structural supports, racks, machinery

Rectangular Tube – used in trusses, platforms, enclosures

Thick-Walled Pipe – for mechanical and pressure-bearing use

Thin-Wall Tubing – for radiators, antenna, railings

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Alloy Grades | 1060,2024, 3003,5052, 6061, 6063, 6082, 7075,8011 |

| Outer Diameter | 6mm – 300mm (round) |

| Wall Thickness | 0.3mm – 20mm |

| Length | 3m, 6m, 12m, or customized |

| Shapes | Round / Square / Rectangular / Oval |

| Surface Finishes | Mill, Anodized, Powder Coated, Brushed, Polished |

| Temper | T4, T5, T6, T651 |

| Standards | ASTM B221, EN 755, GB/T 5237 |

* Custom bending, threading, hole punching and welding also available upon request.

Performance Characteristics and Applications of Aluminum Tubes

I. Performance Characteristics

1. Lightweight Advantage: Aluminum has a density of only 2.7 g/dm³, about one-third that of steel. This allows aluminum tubes to significantly reduce weight while maintaining strength, facilitating transportation and installation.

2. Strong Corrosion Resistance: The naturally formed oxide film on the aluminum surface effectively resists environmental corrosion, especially in humid or chemical environments, extending service life.

3. Outstanding Thermal and Electrical Conductivity: Aluminum’s thermal conductivity is second only to gold and silver, three times that of iron, and its electrical conductivity is close to that of copper, but it is lighter, making it suitable for heat dissipation and power transmission applications.

4. Excellent Processing Performance: Aluminum tubes have good ductility and can be processed into complex shapes through extrusion, bending, welding, and other processes to meet diverse needs.

5. Environmental Protection and Recyclability: Aluminum can be recycled multiple times without losing performance, and its production has low energy consumption, conforming to the concept of sustainable development.

II. Main Applications

1. Construction Industry: Used in door and window frames, curtain wall structures, and handrails, combining aesthetics and weather resistance to enhance the overall quality of buildings. 2. Transportation: Aluminum tubing is widely used in automobiles, airplanes, and other transportation vehicles. Its lightweight design reduces energy consumption and improves fuel efficiency.

3. Electronics and Electrical Appliances: Used as radiators, transformer windings, or capacitor casings, its thermal and electrical conductivity ensures stable equipment operation.

4. Machinery Manufacturing: Used in components such as cylinders and hydraulic pipes to enhance the reliability and durability of mechanical equipment.

5. Household and Daily Necessities: Commonly found in clothes racks, furniture frames, etc., combining practicality and aesthetic value.

With its comprehensive properties, aluminum tubing has become an indispensable material in modern industry and daily life, and its application prospects continue to expand.

Processing & Packaging

CNC sawing and precision cutting

Anodizing (clear, black, bronze, custom colors)

Powder coating and brushing

End capping, shrink wrapping

PE film, export pallets, or wood box crating

ID barcode & product label on each bundle

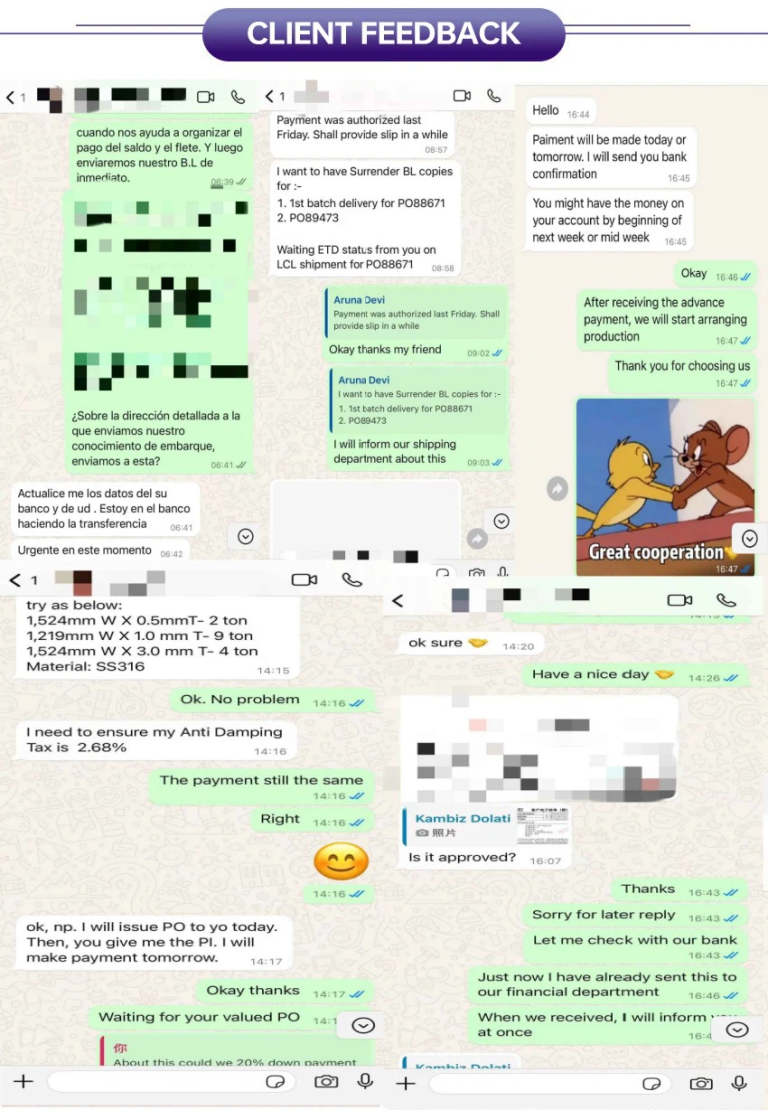

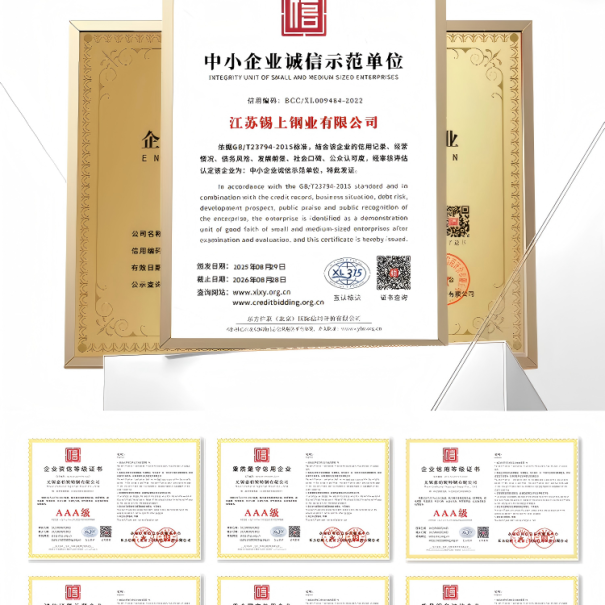

Why Choose Xishang?

- Large inventory of extruded and drawn aluminum pipes

- Full range of structural and mechanical grades

- In-house anodizing, polishing, and CNC cutting

- MOQ starts from 1 ton per size

- Customized length and surface finish available

- ISO/SGS/BV certification and traceable MTC

Frequently Asked Questions

Q1: What’s the difference between 6061 and 6063 aluminum tube?

A:

6061 offers higher strength and is suited for structural use; 6063 has better surface finish and is often used for architectural applications.

Q2: Do you provide anodized aluminum tubes?

A:

Yes. We offer clear and colored anodizing with high adhesion for outdoor and decorative use.

Q3: Can you cut tubes to specific length?

A:

Absolutely. We offer custom cutting from 10mm to 6000mm.

Q4: Are round and square tubes available in the same alloy?

A:

Yes, we can provide round, square, and rectangular tubes in 6061, 6063, 7075 and more.

Q5: Do you support aluminum pipe bending or welding?

A:

Yes. We offer precision bending and welding service if requested.