- You are here:

- Home /

- Products /

- Alloy /

- Urea-Grade Steel

Urea-Grade Steel – Engineered for High Corrosion Urea Environments

Specialized stainless steel and alloy grades tailored for urea synthesis plants and high-pressure equipment. Reliable, certified materials for reactors, strippers, condensers, and piping.

What Is Urea Grade Steel?

Urea-grade stainless steels are specially modified alloys designed to resist carbamate corrosion, intergranular corrosion, and stress corrosion cracking (SCC) in urea production environments.

Urea synthesis involves aggressive ammonium carbamate at high temperature and pressure, requiring:

High Cr-Ni-Mo-N content

Low ferrite content

Strict control of residual elements (e.g., Si, P, S)

Guaranteed resistance to SCC and IGC

These steels are certified and tested per urea application standards (e.g., NACE MR0103, ISO 15156, EN 13445).

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Grade | Description | Application Use |

|---|---|---|

| 316L Mod | Modified 316L with controlled ferrite & impurity levels | Standard for urea synthesis loop piping |

| 25-22-2 | Super austenitic steel with high Cr-Ni-Mo-N content | High-resistance option for urea reactors & strippers |

| 310MoLN | Nitrogen-enhanced high-temp stainless | Urea evaporators, condensers |

| URANUS® B6 | Proprietary urea-resistant alloy | Proprietary reactors / piping |

| Zickler 1.4466 | German-standard modified 316L for urea plants | Condensers, piping systems |

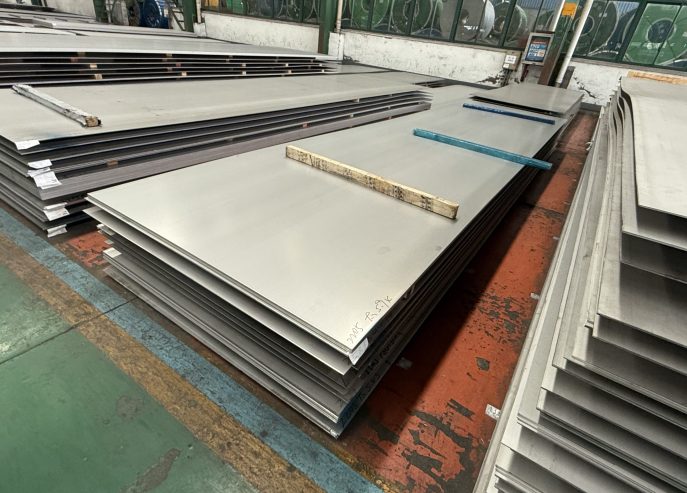

Product Forms: Plate, tube, pipe, bar, flange, forging Standards: ASTM A240, A182, A276, EN 10216-5, NACE MR0175, ASME VIIITested Properties: IGC (per ASTM A262), Ferrite content (<0.5%), SCC resistance, intermetallic phase control

Urea-grade steel is a special type of steel developed to meet the harsh operating conditions of urea production equipment. Its performance characteristics are closely related to its applications, which are described below in detail from both aspects:

1. Performance Characteristics

1.1 Corrosion Resistance

Urea-grade steel exhibits excellent corrosion resistance in the urea production environment, effectively resisting the erosion of corrosive media such as ammonium carbamate, ammonia, and carbon dioxide generated during urea synthesis, ensuring long-term stable operation of the equipment.

1.2 High Strength and Toughness

This type of steel combines high strength with good toughness, capable of withstanding the mechanical stress of urea production equipment under high pressure and high temperature conditions, while avoiding brittle fracture and ensuring the structural integrity of the equipment.

1.3 Weldability

Urea-grade steel undergoes a special alloy design, resulting in excellent weldability. The weld area maintains corrosion resistance and mechanical properties similar to the base material, simplifying equipment manufacturing and maintenance processes.

1.4 Purity and Uniformity

The steel boasts high purity, extremely low levels of harmful impurities, and a uniform microstructure, ensuring that uneven material composition will not cause localized corrosion or performance degradation in the urea production environment.

2. Applications

2.1 Urea Synthesis Tower

Urea-grade steel is the core material for urea synthesis towers, used to manufacture key components such as the tower body and internal parts. It withstands the high-temperature, high-pressure urea synthesis reaction, ensuring synthesis efficiency and safety.

2.2 High-Pressure Equipment

Widely used in high-pressure condensers, evaporators, and other equipment in urea production. These devices process urea solutions under high pressure, requiring materials with excellent corrosion resistance and mechanical strength.

2.3 Piping Systems

Used to manufacture piping systems for urea production units, including pipelines transporting urea solutions, ammonia, carbon dioxide, and other media, ensuring safety and efficiency during media transport.

2.4 Other Key Components

Also used to manufacture key components in urea production such as pumps, valves, and flanges. These components play a crucial role in the urea production process, requiring materials with high reliability.

Urea-grade steel products, with their superior performance characteristics, play an irreplaceable role in urea production equipment and are key materials for ensuring the safe, efficient, and long-term stable operation of urea production.

Processing & Packaging

Ultrasonic tested plates (UT Level II / III)

Precision pipe beveling, polishing, machining

Heat treatment & pickling

Markings: grade + heat no. + spec + QR code

Packaging: export wooden cases, pipe end protectors, desiccant

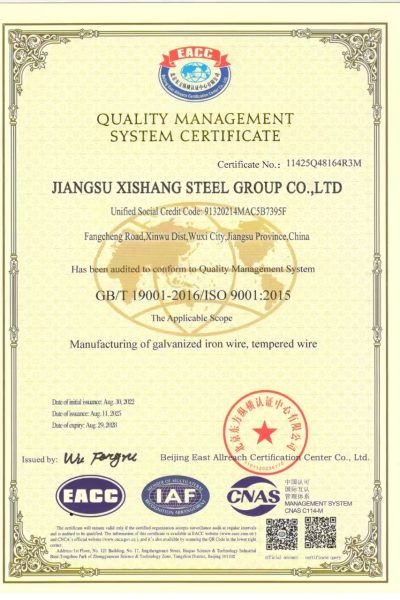

Why Buy From Xishang?

- Years of supply experience to urea equipment OEMs & EPCs

- In-house corrosion testing & PMI before shipment

- Strict ferrite control, intermetallic phase analysis

- Documents per EN10204 3.1 / 3.2 + NDT reports

- Pre-qualified per UREA SYNLOOP piping standards

- Global logistics with project-based packaging & traceability

Frequently Asked Questions

Q1: What is the difference between 316L and 316L Mod for urea service?

A:

316L Mod has tighter control of Si, P, S, and ferrite content, critical for resisting ammonium carbamate corrosion and SCC.

Q2: Do you offer 25-22-2 or 310MoLN for critical urea components?

A:

Yes. We supply plates, tubes, and bars in these high-performance urea grades with full corrosion test certificates.

Q3: Can your material meet urea reactor fabrication codes?

A:

Absolutely. Our products conform to NACE MR0103, ISO 15156, and EN 13445 with UT, IGC and microstructure reports.

Q4: Do you support small project quantities?

A:

Yes. MOQ starts from 100kg. Ideal for maintenance or replacement part supply.

Q5: Can you supply urea-grade flanges and nozzles?

A:

Yes. Custom forged and machined parts for reactors or condensers can be produced with precise ferrite controls.