- You are here:

- Home /

- Products /

- Alloy /

- Titanium Alloys

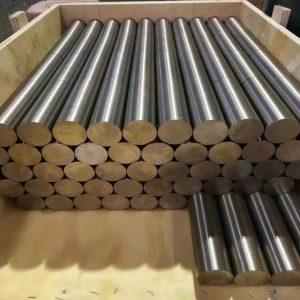

Titanium Alloys – High Strength, Light Weight, Corrosion Resistance

Titanium alloys for aerospace, marine, chemical, medical, and defense use. Stock of commercial and aerospace grades in sheet, bar, pipe and wire.

What Is Titanium Alloy?

Titanium alloys are metallic materials that combine exceptional strength, low density, and corrosion resistance, ideal for:

Aerospace and aviation components

Marine & seawater environments

Corrosive chemical processes

Medical implants and surgical tools

Titanium has a strength-to-weight ratio 2x of steel, and excellent resistance to chloride ion corrosion.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Grade | Alloy Composition | Application Use |

|---|---|---|

| Grade 1 | Pure Titanium (softest) | Heat exchangers, chemical tanks |

| Grade 2 | Pure Titanium (stronger) | Marine, chemical piping |

| Grade 5 / Ti-6Al-4V | Ti + 6% Al + 4% V | Aerospace, high-performance parts |

| Grade 9 | Ti + 3% Al + 2.5% V | Bike frames, aircraft tubing |

| Grade 23 | Ti-6Al-4V ELI (medical) | Implants, surgical instruments |

Standards: ASTM B265 / B348 / B338 / B381 / ISO 5832

Forms: Plate, sheet, bar, rod, tube, wire, forgings, discs

Condition: Annealed / pickled / polished / hot forged

Sizes:

Plate: 0.5mm – 100mm

Bar: Ø6mm – 200mm

Pipe: Ø6mm – Ø219mm (Welded or Seamless)

Wire: Ø0.5mm – 6mm

Titanium alloy products occupy an important position in modern industry due to their unique performance characteristics. The following details their performance characteristics and applications.

1. Performance Characteristics

1.1 High Strength and Lightweight

The density of titanium alloys is approximately 4.5 g/cm³, only 60% of that of steel, yet its strength approaches or exceeds that of some alloy steels, making it an ideal material for lightweight designs.

1.2 Corrosion Resistance

Titanium alloys exhibit excellent corrosion resistance in humid air, seawater, and various chemical media, far superior to stainless steel.

1.3 High Temperature Resistance

Titanium alloys maintain high strength and stability at high temperatures, making them suitable for high-temperature environments.

1.4 Biocompatibility

Titanium alloys are non-toxic and biocompatible, widely used in the medical field.

1.5 Non-magnetic

Titanium alloys are non-magnetic, suitable for equipment sensitive to magnetism.

1.6 Machining Difficulty

The machining of titanium alloys is relatively difficult, requiring special processes and equipment, but this can be optimized through techniques such as powder metallurgy.

2. Applications

2.1 Aerospace

Titanium alloys are used in aircraft structural components, engine parts, etc., to reduce weight and improve fuel efficiency.

2.2 Medical Field

Titanium alloys are used in the manufacture of artificial joints, dental implants, etc., due to their biocompatibility and corrosion resistance.

2.3 Marine Engineering

Titanium alloys are used in seawater desalination equipment, submarines, etc., to resist seawater corrosion.

2.4 Automotive Industry

Titanium alloys are used in the manufacture of high-performance automotive parts, such as engine connecting rods and exhaust systems, to improve vehicle performance.

2.5 Sporting Goods

Titanium alloys are used in the manufacture of golf clubs, bicycle frames, etc., combining lightweight and high strength.

2.6 Chemical Equipment

Titanium alloys are used in the manufacture of reactors, heat exchangers, etc., to resist chemical corrosion.

3. Summary

Titanium alloys, with their lightweight, high strength, and corrosion resistance, are widely used in aerospace, medical, and marine engineering fields. Although processing costs are relatively high, their comprehensive performance makes them an indispensable material in modern industry. In the future, with technological advancements, the application scope of titanium alloys will be further expanded.

Processing & Packaging

Annealing, hot rolling, CNC machining available

Bright, pickled, polished, embosssed or sandblasted surfaces

Custom cut-to-size with ±0.1mm tolerance

PMI & ultrasonic testing for internal soundness

Marking: grade + heat no. + batch + QR code

Packaging: vacuum wrap / wooden case / export crates

Why Buy From Xishang?

- Full range of commercial & aerospace titanium grades

- Precision machining and forming capabilities

- Strict testing: Ultrasonic, tensile, grain size, microstructure

- Medical & ASTM/AMS/NADCAP-grade documentation

- Support for small batch orders and OEM projects

- Fast lead times and seaworthy export packaging

Frequently Asked Questions

Q1: What is the difference between Grade 2 and Grade 5 titanium?

A:

Grade 2 is commercially pure, good for corrosion resistance. Grade 5 (Ti-6Al-4V) offers higher strength, ideal for structural aerospace or medical parts.

Q2: Can you supply titanium for medical use (ELI grade)?

A:

Yes, we offer Ti-6Al-4V ELI (Grade 23) with ASTM F136 / ISO 5832-3 certification for implants.

Q3: Do you support titanium pipe welding and forming?

A:

Absolutely. Tubes can be supplied welded/seamless, with testing per ASME B31.3 or EN standards.

Q4: What machining tolerances do you support?

A:

We offer tight CNC and lathe machining tolerances, including H7/H8 fits for shafts or surgical components.

Q5: Can you ship small quantities globally?

A:

Yes. We support low MOQ (10kg–50kg) and offer door-to-port or door-to-door shipping.