- You are here:

- Home /

- Products /

- Alloy Steel /

- Titanium Alloys /

- Ti-6Al-4V Titanium Alloy Sheet

Ti-6Al-4V Titanium Alloy Sheet

High-Strength, Lightweight Solution for Aerospace, Medical, and Industrial Applications

Ti-6Al-4V (Grade 5) is a α+β type titanium alloy renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Key features include:

- High Strength:Yield Strength 825–895 MPa,Tensile Strength 895–1180 MPa.

- Lightweight:(Density) 4.44 g/cm³, ideal for weight-sensitive applications.

- Corrosion Resistance:Resistant to oxidation, seawater, and harsh chemicals, suitable for marine and chemical environments.

- Biocompatibility:Approved for medical implants and surgical instruments.

- Thermal Stability:Maintains mechanical properties at elevated temperatures (melting point 1630–1650°C).

Chemical Composition

Element | Content (%) | Element | Content (%) |

Ti (Titanium) | Balance | Al (Aluminum) | 5.5–6.75 |

V (Vanadium) | 3.5–4.5 | Fe (Iron) | ≤0.30 |

C (Carbon) | ≤0.08 | N (Nitrogen) | ≤0.05 |

O (Oxygen) | ≤0.20 | H (Hydrogen) | ≤0.015 |

Parameter | Value Range |

Size Range | Thickness: 0.5–50 mm, Width: 500–1500 mm, Length: 1000–6000 mm |

Hardness | 334–341 HB (Brinell Hardness) |

Density | 4.44 g/cm³ |

Yield Strength | 825–895 MPa (Rp0.2) |

Tensile Strength | 895–1180 MPa (Rm) |

Performance Characteristics and Core Applications of Ti-6Al-4V Titanium Plates

I. Performance Characteristics

1. Lightweight and High Strength

1.1. Density is only 4.5 g/cm³, approximately 56% of that of steel, but tensile strength reaches 895-1180 MPa, with a specific strength of 23.5, significantly superior to traditional alloy steel.

1.2. Elastic modulus is 110 GPa, close to that of human bone, effectively reducing stress shielding effects.

2.Corrosion Resistance and Biocompatibility

2.1. A dense oxide film forms on the surface, providing excellent corrosion resistance in seawater and acidic environments.

2.2.Outstanding biocompatibility, with no immune rejection reaction, suitable for long-term implantation.

3.High and Low Temperature Stability

3.1.Operating temperature range -100℃ to 550℃, strong creep resistance at high temperatures and good toughness at low temperatures.

3.2.Melting point 1604-1650℃, thermal conductivity 6.6-6.8 W/(m·K), requiring special processing techniques.

4.Machining Characteristics

4.1.Hardness 33-36 HRC, difficult to cut, requiring high-speed milling and precision forging processes.

4.2.Good weldability, joint strength can reach 90%-95% of the base material, requiring high-purity protective gas.

II. Main Applications

1.Aerospace

1.1.Used in aircraft engine components, landing gear, and helicopter rotors, reducing weight while improving fuel efficiency.

1.2.Missile structural components and aerodynamic components, meeting high strength and high temperature resistance requirements.

2.Medical Implants

2.1.Artificial joints, bone screws, and dental implants, biocompatibility ensures long-term safety.

2.2.Precision instruments such as cardiac stents, elastic modulus matched to human bone biomechanics.

3.Industrial and Civilian Applications

3.1.Ship components and deep-sea equipment, resistance to seawater corrosion extends service life.

3.2.Automotive connecting rods and exhaust systems, lightweighting improves fuel economy.

3.3.High-end sports equipment (such as bicycles and golf clubs), combining strength and toughness.

With its comprehensive properties, Ti-6Al-4V titanium sheets have become a core material in aerospace, medical, and high-end manufacturing fields, driving technological progress and industrial upgrading.

Surface Treatment

- Passivation: Removes surface contaminants and enhances corrosion resistance.

- Polishing: Achieves smooth finishes for medical and aesthetic applications.

- Anodizing: Improves wear resistance and allows for color customization.

- Coating: Optional protective coatings (e.g., TiN, CrN) for extreme environments.

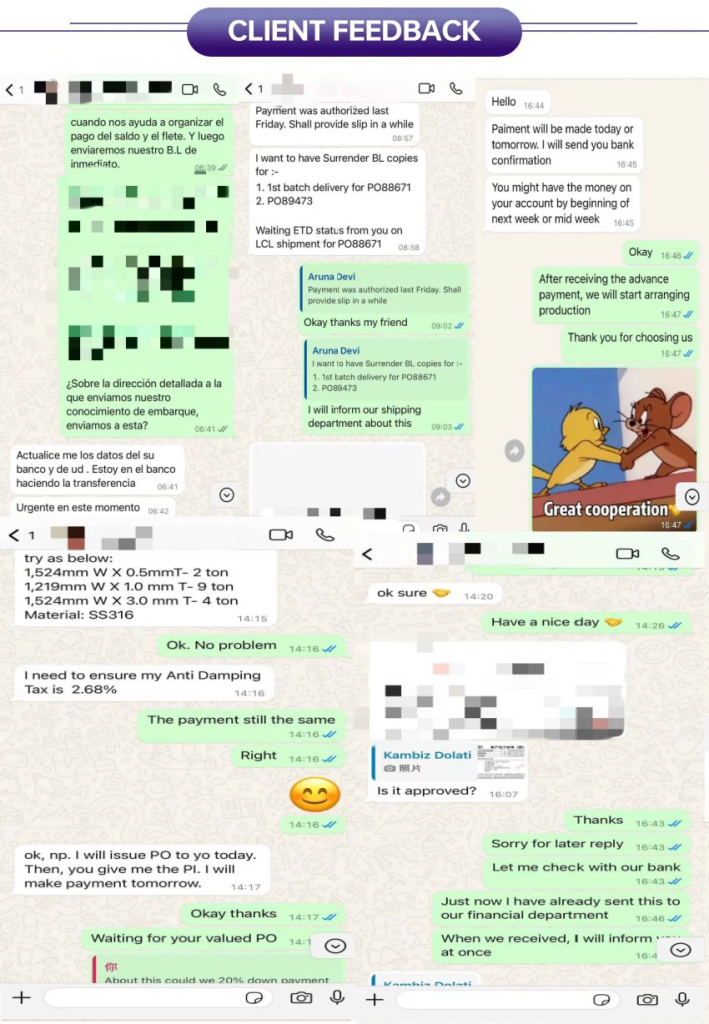

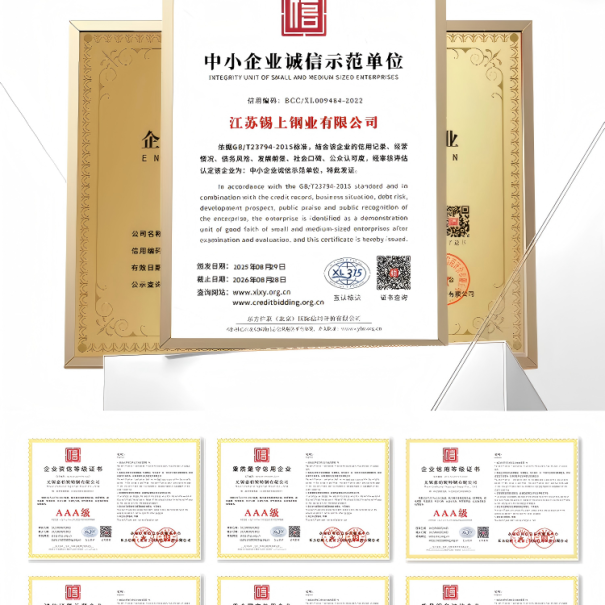

Why Choose Us ?

- Advanced Manufacturing: Precision rolling and heat treatment processes ensure uniform mechanical properties.

- Quality Assurance: Strict adherence to ASTM B348 and ISO standards for consistency.

- Customization: Tailored dimensions, surface finishes, and certifications (e.g., medical-grade ELI variants).

- Global Support: Fast lead times, competitive pricing, and technical assistance for global clients.

Applications & Industries

Aerospace:

Used in aircraft landing gears, wing components, and engine parts.

Medical:

Ideal for implants (e.g., artificial joints, dental implants).

Industrial:

Applied in chemical reactors, marine equipment, and automotive parts.

Frequently Asked Questions

Q1: Is Ti-6Al-4V suitable for high-temperature applications?

A: Yes, it maintains stability up to 500°C, making it ideal for aerospace and energy sectors.

Q2: What are the machining challenges of Ti-6Al-4V?

A: Low thermal conductivity and high chemical reactivity require specialized tools (e.g., carbide cutters) and cooling methods.

Q3: What are the execution standards for Ti-6Al-4V?

A: Ti-6Al-4V (Grade 5) has several key standards:

- AMS 4911: Sheet, strip, and plate (annealed).

- AMS 4928: Bar, forging, and ring (annealed).

- ASTM B265: Titanium and titanium alloy strip, sheet, and plate.

- ASTM F136: Standard specification for wrought titanium-6Al-4V for surgical implant applications.

- MIL-T-9047: Titanium and titanium alloy, bars, and forgings.

- ASME SB-265: Titanium and titanium alloy plate, sheet, and strip.

Q4: What certifications do you offer?

A: ASTM B348, ISO 13485 (medical), and Nadcap for aerospace.

Q5: Lead time and minimum order quantity?

A: Contact our sales team for customized quotes based on volume and specifications.

Ready to source alloy steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.