- You are here:

- Home /

- Products /

- Alloy /

- Superalloys

Superalloys – Engineered to Perform at Extreme Temperatures

High-performance nickel, cobalt and iron-based superalloys designed for high-temperature, high-stress, and corrosive industrial environments. Trusted by aerospace, energy and chemical industries.

What Are Superalloys?

Superalloys, also known as high-performance alloys, are a class of metallic materials designed to:

Maintain strength and surface stability at temperatures above 600°C (1110°F)

Resist oxidation, creep, fatigue and corrosion under stress

Serve in aerospace, turbine engines, nuclear, and chemical plants

Superalloy Categories:

| Type | Base Metal | Typical Grades | Applications |

|---|---|---|---|

| Nickel-based | Ni | Inconel 625, 718, X750 | Turbines, heat exchangers |

| Cobalt-based | Co | Haynes 25, L605, 188 | Jet engines, combustors |

| Iron-based | Fe | A-286, Incoloy 800/825 | Petrochemicals, heat tubes |

These alloys combine solid solution strengthening, precipitation hardening, and oxidation resistance to achieve unmatched reliability in harsh environments.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Grades Available | Inconel 718, GH2132, GH3030, GH3039, GH3128, GH4145, GH4169 |

| Standards | ASTM B564, B637, B168, AMS, NACE MR0175 |

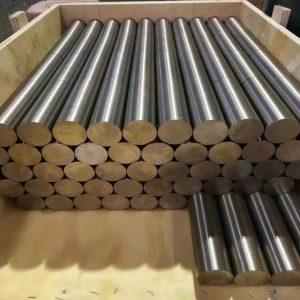

| Forms | Sheet, plate, round bar, rod, wire, tube, pipe, forging |

| Heat Treatment | Solution Annealed, Aged (e.g. 718 – AMS 5662/5663) |

| Sizes | |

| • Plate: 1.5mm – 80mm | |

| • Bar: Ø6mm – Ø250mm | |

| • Pipe: 1/2" – 12", SCH 10–XXS | |

| Delivery Condition | As-forged, solution-treated, or aged |

* Third-party testing: PMI, UT, X-ray, grain size, hardness, tensile, stress rupture

Performance Characteristics and Applications of High-Temperature Alloy Products

1. Core Performance Characteristics of High-Temperature Alloys

1.1 Excellent High-Temperature Strength

Maintains high strength above 650℃, far exceeding that of ordinary alloys.

Excellent creep resistance, with minimal deformation under long-term high temperatures.

1.2 Outstanding Oxidation and Corrosion Resistance

Forms a dense oxide film on the surface, resisting high-temperature oxidation.

Exhibits good resistance to hot corrosion and stress corrosion.

1.3 Good Thermal Fatigue Performance

Maintains structural integrity under repeated thermal cycling.

Excellent thermal shock resistance, adapting to environments with sudden temperature changes.

1.4 Comprehensive Mechanical Properties

Possesses good plasticity and impact toughness at room temperature.

Excellent weldability, meeting the manufacturing requirements of complex structures.

2. Main Applications of High-Temperature Alloy Products

2.1 Aerospace Field

Aero-engines: Turbine blades, combustion chambers, and other hot-end components.

Spacecraft: Rocket engines, thermal protection systems for supersonic aircraft. 2.2 Energy Sector

Gas Turbines: Key components such as turbine discs and guide vanes.

Nuclear Energy: Reactor heating elements and heat exchangers.

2.3 Industrial Sector

Petrochemicals: Linings for cracking furnaces and conversion furnaces.

Glass Manufacturing: Contact components for molten glass.

2.4 Automotive Sector

Turbochargers: Turbine blades and casings.

Exhaust Systems: High-temperature exhaust valves and manifolds.

3. Summary of Application Advantages

High-temperature alloy products, through their unique combination of properties, meet the demands of modern industry for materials to operate in extreme environments. From supersonic aircraft to deep space probes, from high-efficiency generator sets to precision chemical equipment, high-temperature alloys play an irreplaceable role in critical components.

Processing & Packaging

Cut to length, block cutting, centerless grinding

Solution annealing & aging services per AMS

Eddy current, ultrasonic, radiographic testing

Heat number + spec + QR code markings

Wooden crates + vacuum / foil wrap + VCI paper

Why Buy From Xishang?

- Complete range of Ni, Co, Fe-based superalloys

- Support for AMS / ASTM / NACE / ISO standards

- CNC Machining, heat treatment, forging & cut-to-size

- Full traceability with MTC, grain size & microstructure reports

- Export-grade packaging and fast global logistics

- Custom trial production for critical OEMs or EPC projects

Frequently Asked Questions

Q1: Which superalloy is best for 700°C continuous service?

A:

Inconel 625 or 617 are ideal due to high strength and oxidation resistance at 650–800°C range.

Q2: Can I get heat treatment per AMS specifications?

A:

Yes, we support AMS 5662, 5663 (for Inconel 718) and other heat treatment cycles on request.

Q3: Do you offer non-standard bar sizes?

A:

We offer forged or rolled bars in custom diameters and lengths with tight tolerances.

Q4: Can you machine complex turbine shapes?

A:

Yes, CNC and EDM services are available for superalloy components per drawing.

Q5: What is the lead time for superalloy plate or forged parts?

A:

Stock items: 5–7 days. Forged or heat-treated: 10–25 days based on grade and complexity.