- You are here:

- Home /

- Products /

- Alloy /

- Super Duplex Stainless Steels

Super Duplex Stainless Steels – Ultimate Strength Meets Superior Corrosion Resistance

UNS S32750 / S32760 (2507) duplex stainless combines outstanding pitting resistance and mechanical strength. Designed for seawater, chemical, and high-pressure industrial systems.

What Is Super Duplex Stainless Steel?

Super duplex stainless steel is a high alloy dual-phase (ferritic-austenitic) material with:

Twice the yield strength of 304/316

Excellent resistance to pitting, crevice, and stress corrosion cracking (SCC)

Designed for aggressive chloride-rich environments

Good weldability and mechanical performance at high pressure

These steels are widely used when both strength and corrosion resistance are required, making them ideal for structural and process-critical systems.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Grade | UNS No. | PREN | Main Feature |

|---|---|---|---|

| 2507 | S32750 | 42–45 | High strength + seawater & acid corrosion resistance |

| Zeron® 100 | S32760 | 45–50 | Higher impact resistance + erosion/corrosion resistance |

| F55 / 1.4501 | — | 45+ | Equivalent to S32760 |

Standards: ASTM A240 / A479 / A182 / A789 / A790 / EN 10088

Forms: Plate, pipe, tube, bar, forged block, flange, fitting

Dimensions:

• Plate: 3mm – 80mm

• Bar: Ø10mm – 300mm

Pipe: NPS 1/2” – 24”, SCH10–XXS

Condition: Solution Annealed

Performance Characteristics and Applications of Super Duplex Stainless Steel

1. Performance Characteristics

1.1 High Strength and High Hardness

Super duplex stainless steel significantly enhances material strength by precisely controlling the ratio of ferrite and austenite phases (approximately 50% each). Its yield strength can reach more than twice that of ordinary austenitic stainless steel, while maintaining high hardness, making it suitable for high-stress environments.

1.2 Excellent Corrosion Resistance

It performs excellently in chloride environments, with a pitting equivalent (PREN) exceeding 40, far higher than ordinary stainless steel. It effectively resists corrosion from seawater, chemical media, etc., making it suitable for marine engineering and chemical equipment.

1.3 Good Machining Performance

Despite its high hardness, optimized heat treatment processes (such as solution treatment) can improve its cold working and welding performance, reduce cracking tendency, and facilitate the forming of complex structures.

1.4 Fatigue Resistance and Wear Resistance

The duplex structure endows the material with excellent fatigue resistance, making it suitable for dynamic load scenarios; increased surface hardness also enhances wear resistance, extending equipment service life.

2. Product Applications

2.1 Marine Engineering

Used in the manufacture of seawater desalination equipment, subsea pipelines, and ship components. Its resistance to seawater corrosion and biofouling reduces maintenance costs.

2.2 Chemical and Petroleum Industries

Suitable for reactors, heat exchangers, and oil pipelines, maintaining stability in high-temperature, high-pressure, and corrosive media, reducing the risk of leaks.

2.3 Environmental and Energy Equipment

Used in flue gas desulfurization systems and nuclear power plant components. Its acid resistance and high-temperature performance meet the requirements of harsh environments.

2.4 Special Applications

With its high strength, it can be used to manufacture lightweight structural components, such as bridge supports and pressure vessels, reducing weight while maintaining load-bearing capacity.

3. Summary

Super duplex stainless steel achieves a balance between strength, corrosion resistance, and processability through the synergistic effect of its two phases, making it an ideal material for marine, chemical, and other fields. Its applications not only improve equipment reliability but also drive the industry towards high efficiency and environmental protection.

Processing & Packaging

Cutting: Saw, waterjet, laser, plasma

Forged bar or block for custom machining

Pickled, polished, and rough turned finish options

Custom ID stamping with QR code / heat no.

Seaworthy packaging (pallet + oil seal + crate)

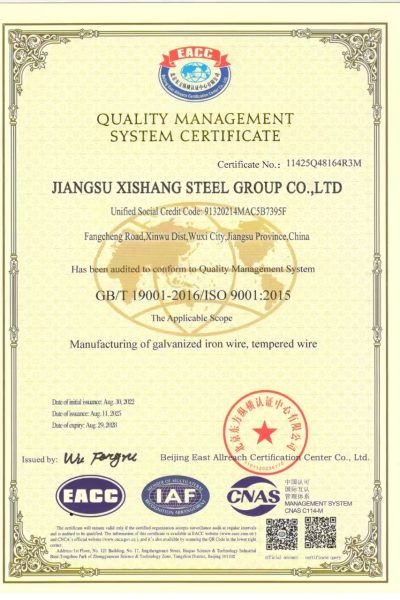

Why Buy From Xishang?

- Certified stock of S32750 / S32760 / Zeron 100

- Dual-phase structure testing (ferrite % balance)

- NACE MR0175 + ASTM + PED documentation

- Machining, forming & welding support available

- PMI, UT, mechanical + corrosion property testing

- Global delivery + fast response

Frequently Asked Questions

Q1: How does Super Duplex differ from regular duplex stainless steel?

A:

Super duplex contains more Cr, Mo, and N, giving higher corrosion resistance and mechanical strength than standard duplex (e.g., 2205).

Q2: What is the maximum chloride level super duplex can handle?

A:

Super duplex like 2507 can typically handle chloride contents up to 1000 ppm depending on temperature and pH.

Q3: Can I weld super duplex materials?

A:

Yes, with proper filler metals (e.g., ERNiCrMo-3) and post-weld cleaning. Ferrite balance should be controlled.

Q4: Is NORSOK or NACE compliance available?

A:

Yes. All our super duplex products can be certified to NACE MR0175 / NORSOK M-650 / ISO 15156 upon request.

Q5: Do you provide forged flanges and pipe fittings?

A:

Absolutely. Elbows, tees, reducers, flanges in S32750/S32760 are available from stock or on order.