- You are here:

- Home /

- Products /

- Alloy /

- Special Stainless Steels

Special Stainless Steels – Engineered for Extreme Environments

We supply premium special-grade stainless steels designed to perform in highly corrosive, high-pressure, high-temperature, or magnetic-sensitive environments.

What Is Special Stainless Steel?

Special stainless steels are a group of enhanced performance alloys that go beyond standard grades like 304/316. They are tailored for:

Extreme corrosion environments (acid, chloride, sulfur)

High temperature service

Anti-sulfide stress corrosion (SSC)

Non-magnetic & controlled magnetic permeability

Oil & gas sour service (H2S, CO₂ exposure)

These grades often come with higher alloy content (Ni, Mo, N, Cu) and stringent mechanical property control.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Grade | Main Feature | Typical Use |

|---|---|---|

| 904L | High Ni & Mo for acid corrosion | Chemical tanks, acid lines |

| 254SMO | Super austenitic, high pitting resistance | Offshore, desalination |

| 309S / 310S | High temperature oxidation resistance | Heat exchangers, kilns |

| 2205 / 2507 | Duplex & super duplex stainless | Oil & gas, marine piping |

| UNS N08904 | Copper-added for sulfuric acid resistance | Fertilizer plants |

| 00Cr20Ni18Mo6CuN (Ultra 904L) | Extreme chloride + acid corrosion | Petrochemical towers |

| UNS S31254 (254SMO) | Excellent pitting resistance (PRE > 42) | Seawater systems |

| 1Cr18Ni9Ti / 321 | Good weldability + thermal fatigue | Food processing & piping |

| Non-Magnetic 316L | Low magnetic permeability for medical / instruments | MRI, electronic enclosures |

| Sulfur-Resistant Steel | Designed for SSC per NACE | Oil drilling, pipelines |

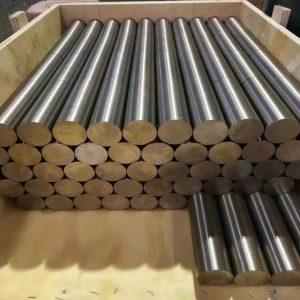

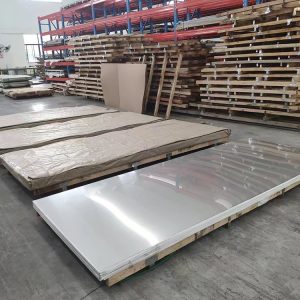

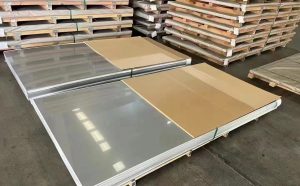

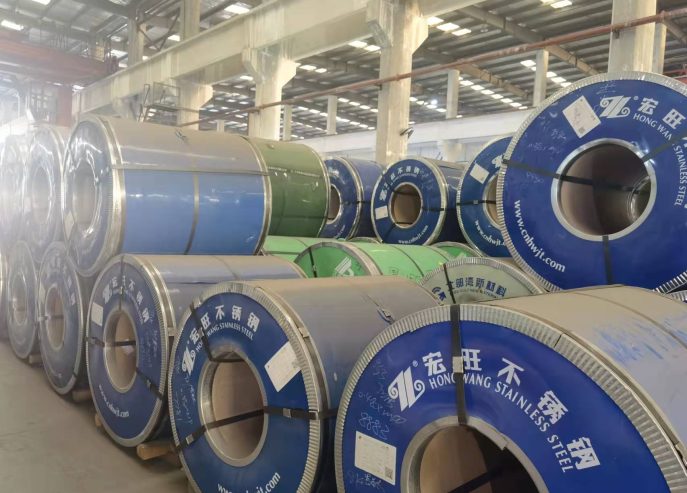

* Delivery: Plate, sheet, pipe, bar, tube, fittings, flanges, forgings

Spec: ASTM A240 / A312 / A182 / EN 1.4539 / N08904 / S32205 / S32750

Special stainless steel products, due to their unique material composition and processing technology, exhibit superior performance and wide application value in multiple fields. The following details their performance characteristics and uses.

1. Performance Characteristics

1.1 Corrosion Resistance

Special stainless steel products possess excellent corrosion resistance, resisting the erosion of various chemical media such as acids, alkalis, and salts. This characteristic allows them to maintain stable performance in harsh environments, extending their service life.

1.2 High Strength and Toughness

Through special alloy design and heat treatment processes, these products combine high strength and high toughness, capable of withstanding significant mechanical stress and impact loads, making them suitable for high-load applications.

1.3 High Temperature Resistance

Special stainless steel products maintain good mechanical properties and chemical stability even at high temperatures, making them suitable for high-temperature operating environments, such as heat treatment equipment and aero-engine components.

1.4 Environmental Protection and Recyclability

These materials meet environmental protection requirements, are recyclable, reduce resource waste and environmental pollution, and embody the concept of sustainable development.

2. Applications

2.1 Industrial Sector

Chemical Equipment: Used in the manufacture of reactors, storage tanks, and pipelines. Corrosion resistance ensures the stable storage and transportation of chemicals.

Oil and Gas: Used in drilling platforms and oil pipelines. High strength and toughness ensure safe operation of equipment under high-pressure environments.

2.2 Construction Sector

High-Rise Buildings: Used for structural support and decoration. Corrosion resistance and aesthetics enhance the overall quality of the building.

Bridges and Tunnels: Provides long-term durability in infrastructure, reducing maintenance costs.

2.3 Medical Sector

Surgical Instruments: Corrosion resistance and biocompatibility make them ideal for medical devices, ensuring medical safety.

Implants: Used in the manufacture of artificial joints and dental implants, meeting the stringent requirements for human implantation.

2.4 Environmental Sector

Wastewater Treatment: Used in the manufacture of filters and pipes. Corrosion resistance ensures long-term use of equipment in harsh water conditions.

Exhaust Gas Treatment: Used in chimneys and exhaust systems. High-temperature resistance ensures high efficiency in exhaust gas treatment.

Processing & Packaging

Precision shearing & CNC machining

Polishing: 2B / BA / No.4 / HL / Mirror

Ultrasonic (UT), PMI, mechanical tests

Oil-coated, vacuum-packed or crate export packaging

Marking: Heat number + batch + grade + QR code (optional)

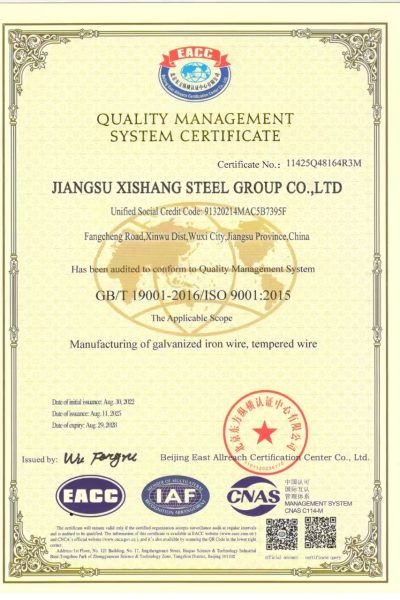

Why Buy From Xishang?

- Over 20 special stainless steel grades in stock

- Full documentation (EN10204 3.1, NACE MR0175, PMI, UT)

- Welding & corrosion resistance consultation

- Slitting, cutting, machining & polishing services

- Fast delivery + small MOQ

- Support for EPC, OEM and MRO projects

Frequently Asked Questions

Q1: What’s the difference between 904L and 316L?

A:

904L has much higher nickel (25%) and molybdenum (4.5%) content, offering better resistance to strong acids like H₂SO₄.

Q2: Is 254SMO better than duplex stainless steel?

A:

For chloride pitting and crevice corrosion, yes. 254SMO (PRE > 42) outperforms 2205 duplex in seawater resistance.

Q3: Do you offer NACE-certified materials for oil & gas?

A:

Yes. All relevant grades can be supplied per NACE MR0175 / ISO 15156 with full traceability and test reports.

Q4: Can you supply non-magnetic stainless with guaranteed permeability?

A:

Yes. We offer low magnetic permeability stainless (<1.005 μr) for sensitive equipment.

Q5: What’s your lead time and MOQ?

A:

Stock items: 3–5 days. MOQ from 50–100kg depending on shape/grade.