- You are here:

- Home /

- Products /

- Alloy /

- Soft Magnetic Alloys

Soft Magnetic Alloys – High Permeability, Low Loss Magnetic Materials

Explore our range of soft magnetic alloys including Permalloy (FeNi), 1J22, 1J85, and Co-based high saturation materials. Tailored for transformer cores, relays, sensors, and EMI shielding.

What Is Soft Magnetic Alloy?

Soft magnetic alloys are ferromagnetic materials with high magnetic permeability, low coercive force, and minimal hysteresis loss. These alloys are ideal for:

Fast magnetization and demagnetization cycles

Low energy loss in alternating magnetic fields

Precision magnetic control in electric components

Common Types:

Nickel-Iron (FeNi) Alloys – e.g., 1J85, 1J50 (Permalloy), high μ

Cobalt-Iron (CoFe) Alloys – e.g., 1J22, high saturation flux density (Bs > 2.3T)

Silicon Steel & Amorphous Alloy – sheet/strip for high-frequency transformers

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Grades Available | 1J85, 1J50, 1J30, 1J22, 1J36, 1J79, 2J4 |

| Common Names | Permalloy, Mumetal, Supermalloy, Hiperco 50, FeNi80/20 |

| Forms | Strip, foil, rod, sheet, core blanks, wires |

| Typical Thickness | 0.05mm – 2mm (strip/foil) |

| Rod Diameter | Ø3mm – Ø50mm |

| Core Types | Toroidal, E-I, C-core, customized shapes |

| Magnetic Properties | |

| • Max. permeability μm > 10,000 | |

| • Coercive force Hc < 1.0 A/m | |

| • Bs up to 2.35T (CoFe) | |

| Processing State | Cold rolled, annealed, hydrogen annealed |

* Custom slitting, stamping, heat treating & magnetic property test reports available.

Performance Characteristics and Applications of Soft Magnetic Products

1. Performance Characteristics

1.1 High Permeability

(1) Soft magnetic materials possess extremely high permeability, enabling efficient magnetic field conduction and significantly reducing hysteresis losses, making them suitable for high-frequency applications.

(2) In alternating magnetic fields, the permeability remains stable, ensuring consistent equipment performance.

1.2 Low Coercivity

(1) Extremely low coercivity means the material is easily magnetized and demagnetized, resulting in low energy loss and suitability for dynamic magnetic field environments.

(2) Low coercivity reduces heat generation and extends equipment lifespan.

1.3 High Resistivity

(1) High resistivity effectively suppresses eddy current losses, especially under high-frequency conditions, significantly improving energy efficiency.

(2) This characteristic makes soft magnetic materials an ideal choice for high-frequency power electronic equipment.

1.4 Moderate Saturation Magnetic Induction

(1) Moderate saturation magnetic induction ensures stable performance even under strong magnetic fields, avoiding magnetic saturation.

(2) Suitable for applications requiring the handling of medium-intensity magnetic fields.

2. Main Applications

2.1 Power Electronics

(1) Used in transformers, inductors, and electronic filters to optimize power conversion efficiency and reduce energy waste.

(2) In switching power supplies, soft magnetic materials improve response speed and stability.

2.2 Motors and Generators

(1) As a core material for motor stators and rotors, it enhances magnetic field conduction, improving motor efficiency and power density.

(2) In generators, it helps stabilize output current, suitable for renewable energy systems.

2.3 Electromagnetic Interference Suppression

(1) Used in the manufacture of EMI filters to effectively absorb and shield electromagnetic interference, protecting sensitive electronic equipment.

(2) In communication equipment, it ensures the clarity and reliability of signal transmission.

2.4 Sensors and Measurement Equipment

(1) As the core of Hall effect sensors and fluxgate sensors, it improves detection accuracy and sensitivity.

(2) In industrial automation, it is used to accurately monitor magnetic field changes, supporting real-time control.

2.5 Emerging Technology Applications

(1) In wireless charging and new energy technologies, soft magnetic materials optimize energy transmission efficiency and support the development of green energy.

(2) Providing efficient solutions for smart grids and electric vehicles.

Processing & Packaging

Strip slitting ±0.01mm tolerance

Hydrogen atmosphere annealing for high permeability

Insulated coating (oxide layer or epoxy) available

Precision stamping and laser cutting

Vacuum packaging + anti-magnetic shielding box

Laser marking with batch number and magnetization direction

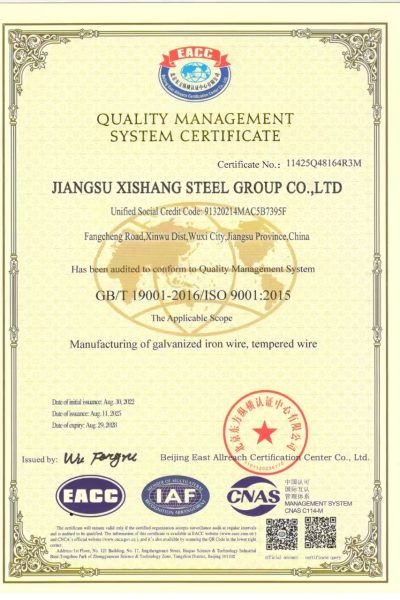

Why Buy From Xishang?

- Wide range of NiFe, CoFe, and Fe-based magnetic alloys

- Core blanks, strip coils, stamped parts & custom geometries

- Hydrogen annealing and magnetic property calibration

- Support for EMI shielding, transformer, sensor & R&D use

- Batch magnetic performance testing (μ, Hc, Bs)

- Low MOQ, fast customization & global shipping

Frequently Asked Questions

Q1: What’s the most common soft magnetic alloy for sensors?

A:

1J85 (FeNi 80/20) and 1J79 are common for precision sensor cores due to their high permeability and low Hc.

Q2: What is the difference between 1J22 and 1J85?

A:

1J22 is a cobalt-based alloy with very high saturation flux density (Bs > 2.3T), ideal for strong magnetic fields. 1J85 is a nickel-iron alloy with ultra-high permeability.

Q3: Do you supply toroidal cores or just raw material?

A:

We supply both. Strip coils, E-I laminations, toroids, rods and machined core blanks are all available.

Q4: How do you guarantee magnetic performance?

A:

We offer test reports for μ, Hc, Bs, and support third-party magnetic calibration if needed.

Q5: Do you offer non-standard sizes or small batch R&D material?

A:

Absolutely. Small MOQ and custom sample preparation are available for labs and OEM prototyping.