- You are here:

- Home /

- Products /

- Alloy /

- Precipitation Hardening Stainless Steels

Precipitation Hardening Stainless Steels – Strength Meets Corrosion Resistance

We supply a full range of PH stainless steels including 17-4PH (S17400), 15-5PH and 13-8Mo. Ideal for precision parts requiring excellent strength, wear resistance and dimensional stability.

What Is Precipitation Hardening Steel?

Precipitation Hardening (PH) stainless steels are a class of martensitic or semi-austenitic steels strengthened by a heat treatment process that precipitates fine particles to enhance mechanical properties.

Key Features:

High strength-to-weight ratio

Corrosion resistance comparable to austenitic stainless steels (304, 316)

Good machinability and dimensional control

Age-hardenable with no distortion

Magnetic (17-4PH, 15-5PH) or non-magnetic (A286, depending on condition)

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Product Forms | Round bar, flat bar, sheet, plate, forging, disc, block |

| Grades Available | 17-4PH (UNS S17400), 15-5PH, 13-8Mo, A286, 17-7PH |

| Standards | ASTM A564, A693, A705, AMS 5643, EN 1.4542 |

| Bar Size | Ø6mm – Ø400mm |

| Plate Thickness | 3mm – 150mm |

| Delivery State | Annealed (Condition A), H900 / H1025 / H1150 etc. |

| Heat Treatments | Solution Annealed + Aging (Precipitation Hardened) |

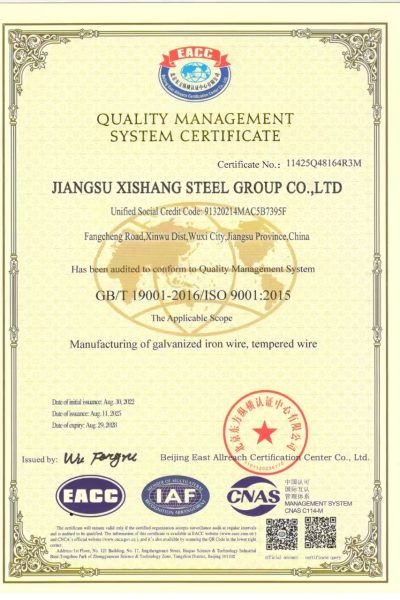

| Certifications | EN10204 3.1 / 3.2, AMS, NACE, ISO 9001 |

* Third-party inspections, NDT, tensile & hardness testing available.

Performance Characteristics and Applications of Precipitation-Hardening Stainless Steel Products

I. Performance Characteristics

1. High Strength and Hardness

Precipitation-hardening stainless steel precipitates intermetallic compounds through heat treatment (such as aging treatment), significantly improving material strength. Tensile strength can reach over 1000 MPa, and hardness can reach HRC30-40, far exceeding ordinary stainless steel.

1.1 Aging Strengthening Mechanism

During heat treatment, elements such as copper and aluminum precipitate to form strengthening phases, achieving high strength while maintaining toughness.

1.2 Comprehensive Mechanical Properties

It possesses high strength, high hardness, and good toughness, with excellent fatigue strength and wear resistance, making it suitable for high-stress environments.

2. Corrosion Resistance

High chromium content (12-18%) forms a dense oxide film, resisting corrosion from the atmosphere, fresh water, steam, and various acid and alkali media, approaching the level of 304 stainless steel.

2.1 Environmental Adaptability

It exhibits stability and long service life in harsh environments such as marine and chemical plants.

2.2 Surface Treatment Compatibility

Supports polishing, electroplating, and other processes, enhancing both aesthetics and functionality.

3. Heat Treatment Controllability

By adjusting heat treatment processes (such as solution treatment + aging), material properties can be precisely controlled to meet diverse application requirements.

II. Main Applications

1. Aerospace Industry

Used in the manufacture of aircraft landing gear, engine components, fasteners, etc., meeting requirements for high strength, lightweight, and corrosion resistance.

2. High-End Industrial Equipment

Used in chemical equipment, marine engineering, nuclear energy equipment, etc., ensuring stable operation of equipment in high-temperature, high-pressure, and corrosive environments.

3. Medical and Precision Instruments

Used in surgical instruments, implants, optical components, etc., possessing biocompatibility, high precision, and sterilization resistance.

4. Special Tools and Molds

Manufacturing high-precision molds, cutting tools, and wear-resistant parts, improving production efficiency and service life.

Precipitation-hardening stainless steel, with its unique combination of properties, has become an irreplaceable material in high-end manufacturing fields, widely used in scenarios with stringent requirements for strength, corrosion resistance, and reliability.

Processing & Packaging

Custom cutting (waterjet/plasma/saw)

Solution annealing + aging heat treatment

Hardness, tensile, elongation testing per batch

Turning, grinding, polishing (Ra ≤ 0.8µm)

Wooden crate, rust-proof wrap, ID marking

Why Buy From Xishang?

- Full series of PH grades including 17-4PH, 13-8Mo, A286

- Heat treatment options: H900 to H1150M

- CNC machining, rough/final turned finish available

- Tight tolerance and dimensional control

- Low MOQ, stock ready, global shipping

- Corrosion resistance + high yield strength for critical parts

Frequently Asked Questions

Q1: What’s the difference between 17-4PH and 15-5PH?

A:

Both are PH stainless steels. 15-5PH offers better toughness and slightly better corrosion resistance due to its reduced delta ferrite content compared to 17-4PH.

Q2: What is “H900” or “H1150” condition?

A:

These refer to heat treatment aging temperatures which determine final mechanical properties. H900 = high strength, H1150 = improved ductility.

Q3: Can you provide forged blanks in PH stainless?

A:

Yes. Forgings, rough turned bars and large plates for machining are available.

Q4: What industries commonly use PH steels?

A:

Aerospace, precision machinery, petrochemical, pump/valve, food equipment, mold tooling, marine and defense.

Q5: Do you support small quantity machining trials?

A:

Absolutely. Low MOQ and custom-machining support provided for new project evaluations.