- You are here:

- Home /

- Products /

- Alloy Steel /

- Super Austenitic Stainless Steels /

N08026 Nickel Alloy Tube

N08026 is a nickel-iron-chromium-molybdenum-copper alloy designed for exceptional corrosion resistance in harsh environments, particularly against sulfuric acid, phosphoric acid, and chloride-containing media. Its key features include:

- High corrosion resistance: Resistant to pitting, crevice corrosion, and stress corrosion cracking (SCC).

- Excellent weldability: Suitable for TIG, MIG, and resistance welding with minimal post-weld heat treatment.

- Thermal stability: Maintains mechanical properties at temperatures up to 990°C.

Chemical Composition (wt%)

|

Element |

Content Range |

|

Ni |

33.00–37.20 |

|

Fe |

24.40–37.90 |

|

Cr |

22.00–26.00 |

|

Mo |

5.00–6.70 |

|

Cu |

2.00–4.00 |

|

C |

≤0.030 |

|

Mn |

≤0.10 |

|

Si |

≤0.50 |

|

N |

0.10–0.16 |

|

P, S |

≤0.030 each |

Parameter | Value/Range |

Dimensions | OD: 3–219 mm, WT: 0.5–35 mm |

Density | 8.2 g/cm³ |

Tensile Strength | ≥620 MPa |

Yield Strength | ≥270 MPa |

Hardness (HB) | 120–180 |

I.N08026 alloy pipe is a high-performance nickel-based alloy with the following notable properties:

1. Excellent Corrosion Resistance: It performs exceptionally well in oxidizing and moderately reducing environments, resisting corrosion from a wide range of chemical media and is particularly suitable for harsh environments containing chloride ions and hydrogen sulfide.

2. High-Temperature Stability: It maintains stable mechanical properties at high temperatures (annealing temperature range of 1121-1204°C), with outstanding high-temperature strength and heat resistance.

3. Good Processability: It is easy to weld and form, and its internal structure can be further optimized through processes such as forging and heat treatment.

4. Excellent Mechanical Properties: It combines high strength and toughness, making it suitable for long-term use under high-pressure and high-stress conditions.

II. N08026 alloy pipe is widely used in the following applications:

1. Chemical Equipment: It is used in the manufacture of reactors, pipelines, and other equipment, where its corrosion resistance extends equipment life.

2. Offshore Platforms: It resists seawater corrosion and high-temperature environments and is suitable for oil and gas production equipment.

3. Energy and Power: Used in boilers, heat exchangers, and condensers, its high-temperature stability ensures system safety.

4. Food Processing: Excellent hygienic performance meets food safety standards.

5. Aerospace: Corrosion resistance and high-temperature performance meet special requirements in extreme environments.

Surface Treatment

- Pickling: Removes oxide layers post-processing.

- Passivation: Enhances corrosion resistance via nitric acid treatment.

- Polishing: Available in BA, No.4, or mirror finishes per ASTM A480.

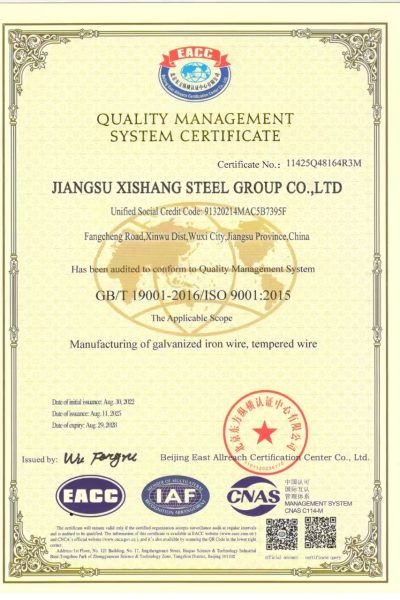

Why Choose Us ?

- Certified Material: Traceable to ASTM/ASME standards.

- Custom Fabrication: Laser cutting, CNC bending, and welding services.

- Global Supply Chain: Stock availability in North America, Europe & Asia.

Applications & Industries

Oil & Gas Industry:

Used in pipelines and equipment for sour gas (H₂S) environments due to high resistance to stress corrosion cracking.

Chemical Processing:

Suitable for reactors, heat exchangers, and storage tanks handling acidic or oxidizing media.

Marine Engineering:

Applied in seawater systems, condensers, and offshore structures for superior chloride corrosion resistance.

Frequently Asked Questions

Q1: Is N08026 suitable for high-temperature applications?

A1: Yes, with stable properties up to 990°C.

Q2: What welding methods are recommended?

A2: TIG/MIG using ERNiCrMo-3 filler.

Q3: How does N08026 compare to Alloy 20 (N08020)?

- N08026: Higher nickel/molybdenum content for broader acid resistance (including hot sulfuric acid).

- Alloy 20: Optimized for medium-concentration sulfuric acid but less versatile in mixed acids.

Q4: Temperature limits?

- Continuous service: -196°C to 600°C (short-term peak: 650°C).

Q5: How does N08026 perform in corrosive environments?

N08026 exhibits exceptional resistance to:

- Oxidation: Forms a protective oxide layer at high temperatures.

- General Corrosion: Performs well in acidic and alkaline media, including sulfuric and phosphoric acids.

- Pitting and Crevice Corrosion: Molybdenum content enhances resistance to localized attack in chloride solutions.

- Stress Corrosion Cracking: Immune to cracking in chloride and sulfide-containing environments, making it ideal for oil and gas applications.

Q6: What are the applicable standards for N08026 alloy tubes?

N08026 alloy tubes comply with several internationally recognized standards, ensuring quality and performance consistency across applications. Key standards include:

- ASTM B729: Covers seamless nickel and nickel alloy tubes for heat exchangers and condensers, specifying dimensions, tolerances, and testing requirements.

- ASTM B564: Pertains to seamless nickel and nickel alloy pipes, ensuring material composition, mechanical properties, and corrosion resistance meet industry benchmarks.

- ASTM B906: Focuses on wrought nickel and nickel alloy fittings, including tubes, with guidelines for manufacturing and inspection.

- ASME SB729: Aligns with ASTM B729 but is adopted by the American Society of Mechanical Engineers (ASME) for pressure vessel components, ensuring suitability for high-stress environments.

- DIN 17775: German standard for seamless nickel and nickel alloy tubes, emphasizing dimensional accuracy and material purity for European markets.

- EN 10296-1: European standard for seamless nickel and nickel alloy tubes, covering chemical composition, mechanical properties, and testing protocols to ensure compliance with regional safety regulations.

Ready to source alloy steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.