- You are here:

- Home /

- Products /

- Alloy /

- Monel Alloys

Monel Alloys – The Marine-Grade Nickel-Copper Solution

Monel 400 and K500 offer outstanding resistance to seawater, acids, alkalis and pressure. Ideal for shipbuilding, chemical processing, oil tools, valves and heat exchangers.

What Is Monel?

Monel® is a trademarked family of nickel-copper alloys known for their exceptional resistance to seawater and chemical corrosion, along with good mechanical strength and toughness.

The most used grades include:

Monel 400 – 67% Ni + 30% Cu, excellent seawater & acid resistance

Monel K500 – Precipitation-hardened version of Monel 400 with higher strength & hardness

Core Properties:

Superior resistance to saltwater, hydrofluoric acid, sulfuric acid

High strength and toughness, even at sub-zero temperatures

Maintains performance under high pressure and thermal stress

Excellent machinability, weldability and fatigue resistance

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Forms Available | Sheet, plate, pipe, tube, round bar, wire, flange, fittings |

| Grades | Monel 400 (UNS N04400), Monel K500 (UNS N05500) |

| Standards | ASTM B127 (sheet), B165 (pipe), B164 (bar), B366/B564 (fittings) |

| Plate Thickness | 1mm – 80mm |

| Bar Size | Ø6mm – Ø300mm |

| Pipe Size | 1/2” – 12” NPS, SCH 10–XXS |

| Condition | Annealed, hot forged, cold drawn, hardened & tempered |

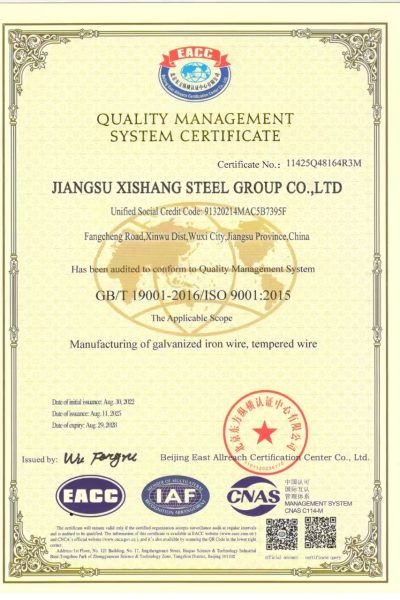

| Certifications | ASTM, EN10204 3.1/3.2, NACE MR0175, ISO, TUV |

Monel alloy is a corrosion-resistant alloy primarily composed of nickel and copper, widely used in various industrial fields due to its superior performance. The following is a detailed analysis of its performance characteristics and applications:

1. Performance Characteristics

Monel alloy’s unique properties enable it to perform exceptionally well in extreme environments.

1.1 Corrosion Resistance

Monel alloy exhibits excellent performance in reducing acids and strong alkalis. Its resistance to seawater corrosion is superior to nickel steel and high-nickel steel, and it remains stable in non-oxidizing acids such as hydrochloric acid and hydrofluoric acid. Its corrosion resistance primarily stems from the passivating effect of nickel, which forms a dense oxide film on the surface, preventing further corrosion. At high temperatures, Monel alloy exhibits high resistance to caustic alkalis, remaining stable even in boiling caustic alkali solutions.

1.2 Mechanical Properties

Monel alloy possesses high strength and high hardness while maintaining good plasticity and toughness. Its tensile strength, yield strength, elongation, and reduction of area are all superior to ordinary stainless steel, allowing it to maintain structural integrity even under complex stresses.

1.3 Physical Properties

Monel alloys possess high thermal and electrical conductivity, making them excellent for applications requiring rapid heat or electrical conduction. Their moderate coefficient of thermal expansion allows them to maintain dimensional stability even in environments with significant temperature variations.

2. Applications

The superior properties of Monel alloys have led to their widespread application in numerous fields.

2.1 Marine Engineering

Monel alloys exhibit excellent resistance to seawater corrosion and are commonly used in the manufacture of ship equipment, offshore platform structural components, and seawater desalination plants.

2.2 Chemical Industry

Monel alloys demonstrate outstanding corrosion resistance in reducing acids and strong alkalis, making them suitable for manufacturing chemical equipment, pipes, valves, pumps, etc.

2.3 Aerospace

The high strength and corrosion resistance of Monel alloys make them suitable for manufacturing aircraft engine components and spacecraft structural components.

2.4 Energy Sector

Monel alloys are used in the nuclear industry to manufacture nuclear reactor components and in the petrochemical industry to manufacture corrosion-resistant pipes and valves. Monel alloys, with their excellent corrosion resistance, mechanical properties, and physical properties, are widely used in marine engineering, chemical industry, aerospace and other fields, and have become an indispensable material in modern industry.

Applications

- Shipbuilding & Marine Engineering: shafts, pumps, valves, fasteners

- Chemical Plants: heat exchangers, vessels, pipelines

- Oil & Gas: downhole tools, valves, couplings

- Acid Production Systems: HF acid, sulfuric, hydrofluoric acid environments

- Cryogenic Equipment: LNG handling components

- Mechanical Components: springs, shafts, fasteners

Processing & Packaging

Waterjet/plasma/laser cutting for sheet & bar

Precision turning for shafts & fittings

Ultrasonic (UT), X-ray (RT), PMI, hardness & tensile tests

Heat number + QR code marking

Wooden crate or seaworthy packaging with rust-proof wrapping

Why Buy From Xishang?

- Direct stock of Monel 400/K500 in various shapes

- Small MOQ & cut-to-length support

- CNC machining, drilling, threading & forming service

- Support for critical marine and chemical-grade applications

- Third-party testing (SGS, TUV) & PMI available

- Fast delivery to ports worldwide

Frequently Asked Questions

Q1: What is the key difference between Monel 400 and K500?

A:

K500 is age-hardened, offering significantly higher strength and hardness, while Monel 400 is softer but extremely corrosion-resistant.

Q2: Can Monel alloys be used in acid environments?

A:

Yes. Monel 400 is excellent for hydrofluoric and sulfuric acids, especially in non-oxidizing conditions.

Q3: Do you supply Monel pipes with NACE certification?

A:

Yes. Monel 400/K500 pipes can be supplied per NACE MR0175/ISO 15156 requirements.

Q4: What’s your minimum order quantity for Monel bar?

A:

As low as 1 piece for standard sizes in stock; 50–100kg for cut-to-length orders.

Q5: Can I request forged Monel flanges and fittings?

A:

Absolutely. We provide Monel socket weld/threaded flanges, elbows, tees, and custom forged components.