- You are here:

- Home /

- Products /

- Alloy /

- Inconel Alloys

Inconel Alloys – Unmatched Performance in Extreme Heat and Corrosion

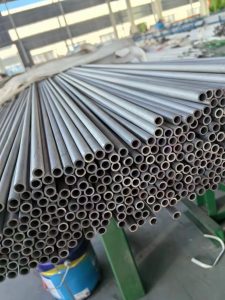

We supply a wide range of Inconel alloys including 600, 625, 718, X-750 for demanding high-temperature and corrosive environments. Trusted by aerospace, power, chemical and marine industries.

What Is Inconel?

Inconel® is a family of nickel-chromium-based superalloys developed by Special Metals Corporation. It is designed for service in extreme environments involving:

High temperature (up to 1000°C).Severe corrosion and oxidation.High pressure or cyclic stress.Saltwater or chemical attack.

Key Properties:

Exceptional thermal fatigue resistance.High creep and rupture strength.Excellent resistance to chloride stress corrosion cracking (SCC).Maintains strength and shape under thermal cycling.

Popular Grades:

Inconel 600 – Oxidation + chloride resistance

Inconel 625 – Strength + seawater + acid corrosion

Inconel 718 – High strength + creep resistance (age-hardenable)

Inconel X-750 – Aerospace, gas turbine, spring applications

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Forms Available | Pipe, plate, sheet, bar, wire, forging blank |

| Grades | Inconel 600, 601, 625, 718, 690, 725, X-750, 617 |

| Standards | ASTM B168, B446, B443, B564, AMS 5662/5663/5596 |

| Plate Thickness | 0.8mm – 100mm |

| Bar Diameter | 6mm – 300mm |

| Pipe Size | NPS 1/2” – 20”, SCH 10–160 / XXS |

| Condition | Annealed, hot rolled, solution treated, aged |

* Alloys available in solution-annealed or age-hardened condition. 3.1 / 3.2 MTC & NACE MR0175 available.

Inconel alloy is a nickel-based superalloy widely used in extreme environments due to its superior performance. The following is a detailed analysis of its performance characteristics and applications:

1. Performance Characteristics

The core performance of Inconel alloy stems from the synergistic effect of its nickel-based composition and alloying elements (such as chromium, molybdenum, and cobalt), forming a stable austenitic structure that endows the material with excellent corrosion resistance, high-temperature strength, and oxidation resistance.

1.1 Corrosion Resistance

It exhibits excellent performance in both oxidizing and reducing environments, resisting corrosion from various acid, alkali, and salt solutions. Suitable for strong acid and alkali environments, such as chemical equipment and marine engineering, ensuring long-term stable operation.

1.2 High-Temperature Performance

It maintains high strength at high temperatures, exhibiting excellent creep and fatigue resistance, suitable for extreme temperatures above 1000°C. It has significant oxidation resistance, forming a protective oxide layer and extending service life.

1.3 Mechanical Properties

It combines high strength, high toughness, and high ductility, making it suitable for complex machining and dynamic load scenarios. 1.4 Fatigue Resistance

Excellent weldability, allowing for joining through various processes, facilitating manufacturing and maintenance.

2. Main Applications

Inconel alloys’ unique properties make them the material of choice in several key areas.

2.1 Aerospace

Used in engine components, combustion chambers, and turbine blades, they withstand high-temperature and high-pressure environments, ensuring flight safety.

2.2 Energy Sector

Applications in nuclear reactors and gas turbines, providing stability and reliability, supporting efficient energy conversion.

2.3 Chemical and Marine Engineering

Used in the manufacture of reactors and piping, resisting corrosive media and ensuring equipment integrity.

2.4 Medical Devices

Applications in implants and surgical instruments, ensuring biocompatibility and long-term durability.

3. Summary

Inconel alloys, with their corrosion resistance, high-temperature strength, mechanical properties, and fatigue resistance, are ideal for extreme environments. It is widely used in aerospace, energy, chemical and medical fields, driving technological progress and industrial development.

Processing & Packaging

CNC machining, drilling, threading, grinding

Solution annealing or precipitation hardening (718)

PMI, ultrasonic, hardness, tensile & elongation test

Export packaging: vacuum wrap + crate/pallet

Part ID stamping with heat batch + QR/barcode options

Why Buy From Xishang?

- Wide selection of Inconel grades in sheet, bar, pipe

- Precision cutting, turning, heat treatment & machining

- High-performance alloys for aerospace and nuclear specilic

- Welding guidance and matched filler recommendations

- Low MOQ with fast global dispatch

- Third-party inspection by SGS / TUV supported

Frequently Asked Questions

Q1: What's the main difference between Inconel 625 and 718?

A:

625 is non-age-hardenable, excellent for corrosion; 718 is age-hardenable, used when high strength and creep resistance are critical, such as in turbines or engines.

Q2: Can Inconel alloys be welded?

A:

Yes. Inconel can be GTAW or GMAW welded using Inconel filler metals like ERNiCrMo-3 or 718 filler.

Q3: Do you provide Inconel sheets for thermal fixtures?

A:

Yes, Inconel 600, 601, and 718 plates are ideal for baskets, trays, and jigs in heat treating processes.

Q4: Do you support cut-to-size and machining?

A:

Absolutely. We offer custom lengths, drilled plates, and CNC-milled components to drawing.

Q5: Are your Inconel products certified?

A:

Yes. MTC + AMS + NACE certifications available. We also support third-party audits and inspection.