- You are here:

- Home /

- Products /

- Stainless Steel /

- Incoloy Alloys

Incoloy Alloys – High-Temperature Corrosion-Resistant Nickel-Iron Alloys

Incoloy alloys are designed for service in extreme environments combining heat, pressure, and corrosive media. Ideal for chemical processing, nuclear, marine, and thermal treatment systems.

What Is Incoloy?

Incoloy® is a family of nickel-iron-chromium-based superalloys manufactured by Special Metals Corporation. Unlike Inconel, which is optimized for oxidation and strength at ultra-high heat, Incoloy offers a balance between:

- High strength at elevated temperatures

- Outstanding resistance to sulfuric and phosphoric acid

- Stress-corrosion and pitting resistance in seawater and chlorides

- Excellent structural stability under thermal cycling

Most Popular Incoloy Grades:

Incoloy 800 / 800H / 800HT – High strength + oxidation resistance

Incoloy 825 – Corrosion resistant in reducing + oxidizing acid

Incoloy 925 / 945 / A286 – High strength and corrosion resistance, often used in oil & gas

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Product Forms | Seamless pipe, plate, bar, forging, strip, tube, wire |

| Grades Available | Incoloy 800H, 800HT, 825, 925, A286, 903 |

| Standards | ASTM B163/B407/B409/B514/B564, DIN 1.4876, 1.4958, 2.4858 |

| Plate Thickness | 1mm – 100mm |

| Bar Diameter | Ø6mm – 300mm |

| Pipe Sizes | 1/2” – 20” NPS / SCH 10 – XXS |

| Finish | Annealed, polished, pickled, cold drawn, ground |

* MTC, third-party inspection, EN10204 3.1/3.2 available.

Incoloy alloys are a class of high-performance nickel-based alloys widely used in industry due to their excellent corrosion resistance, high-temperature strength, and stability. The following is a detailed description of their performance characteristics and applications:

1. Performance Characteristics

The performance characteristics of Incoloy alloys are mainly reflected in the following aspects:

1.1 Corrosion Resistance

Incoloy alloys exhibit excellent corrosion resistance in both oxidizing and reducing environments, resisting the erosion of various acid, alkali, and salt solutions. The oxide film formed on their surface effectively prevents further corrosion, maintaining their stability in harsh chemical environments.

1.2 High-Temperature Strength

These alloys maintain high mechanical strength and hardness at high temperatures, and are not prone to creep or deformation. This makes them ideal for high-temperature applications, such as furnaces and heat exchangers.

1.3 Thermal Stability

Incoloy alloys have a low coefficient of thermal expansion, resulting in minimal dimensional changes with temperature variations, ensuring structural integrity under thermal cycling conditions. 1.4 Mechanical Properties

It possesses good ductility and toughness, making it easy to process into various shapes while maintaining high strength and fatigue resistance, adapting to complex working conditions.

2. Applications

Incoloy alloys have a wide range of applications, mainly covering the following fields:

2.1 Chemical Industry

Used in the manufacture of reactors, pipelines, and valves to handle corrosive media such as strong acids and alkalis, ensuring long-term stable operation of equipment.

2.2 Oil and Gas

Providing corrosion-resistant and high-temperature-resistant solutions in high-temperature and high-pressure environments, such as oil well equipment and refinery pipelines.

2.3 Aerospace

Used in the manufacture of aircraft engine components and structural parts to withstand extreme temperatures and stresses, ensuring flight safety.

2.4 Energy Sector

Used in heat exchangers and steam generators in nuclear power plants and thermal power plants to improve energy conversion efficiency.

2.5 Medical Devices

Suitable for surgical instruments and implants, utilizing its biocompatibility and corrosion resistance to ensure medical safety. 3. Conclusion

Incoloy alloys, with their comprehensive properties, have become the preferred material in chemical, petroleum, aerospace, energy, and medical fields. Their corrosion resistance, high-temperature strength, and thermal stability ensure reliability and durability in extreme environments, driving advancements in industrial technology.

Processing & Packaging

Hot rolled or cold drawn processing

Annealing or bright solution heat treatment

PMI, UT, hardness, tensile & elongation tests

Clear heat number stamping + waterproof label

Packaging: plastic wrap + wooden box / crate / pallet

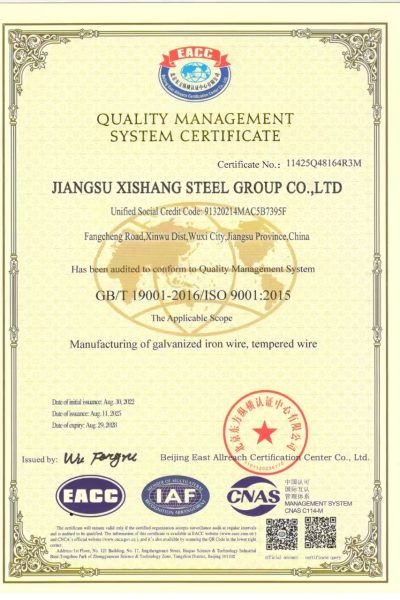

Why Buy From Xishang?

- Full stock of Incoloy 800/825 pipe, sheet, bar & wire

- Cut-to-length, threading, CNC machining service

- Weldability guidance + filler suggestions (e.g., ERNiCrMo-3)

- Precision forging + solution annealing available

- Corrosion simulation & technical support

- Global supply network with fast dispatch

Frequently Asked Questions

Q1: What's the difference between Incoloy 800 and 825?

A:

800 is mainly for high-temperature stability and oxidation resistance; 825 is used more for corrosion resistance in acids like sulfuric or phosphoric.

Q2: Can Incoloy 825 be used in seawater?

A:

Yes. It has excellent resistance to seawater corrosion, pitting, and crevice attack, making it suitable for marine systems.

Q3: Do you supply seamless pipes and heavy plates in Incoloy grades?

A:

Yes, we offer both hot-rolled plates up to 100mm and seamless tubes from NPS 1/2” to 20”.

Q4: What is the welding condition of Incoloy alloys?

A:

Most Incoloy grades can be welded using standard nickel-based filler wires (e.g., ERNiCrMo-3) with preheat control.

Q5: Do you offer low MOQ or urgent delivery?

A:

Absolutely. Stocked items can ship in 3–5 days, and small batch trial orders are welcome.