- You are here:

- Home /

- Products /

- Alloy /

- Hydropower Steel

Hydropower Steel – Precision Steel for Clean Energy Infrastructure

We supply high-quality alloy and structural steels for hydropower applications, including turbine runners, penstocks, bearing shafts, spiral casings and generator components.

What Is Hydropower Steel?

Hydropower steel is a specialized structural and alloy steel used in dam, hydropower station, and turbine construction, engineered to meet the challenges of:

High pressure water impact erosion

Cyclic stress & vibration fatigue

High weldability and impact resistance

Excellent low-temperature toughness

These materials require fine grain structure, excellent homogeneity, and often NDT inspection to ensure structural safety and lifespan in critical energy applications.

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Forms | Heavy plate, forged block, ring, shaft, pipe |

| Typical Grades | Q345D/E, 20Mn5, 30CrMo, 30CrNiMo8, 16MnDR, HY100, ASTM A350 LF2 |

| Thickness (Plate) | 10mm – 300mm |

| Forged Shafts | Ø100mm – 1000mm, L up to 12m |

| Standards | GB/T 700, GB/T 11251, EN 10028, ASTM A350, ASME SA266 |

| Condition | Q+T, annealed, normalized, UT Level II / III |

| Inspection | UT, RT, MT, Charpy V-notch at -20°C/-40°C |

100% Ultrasonic Testing + Z15/Z25 lamellar tear resistance available.

Performance Characteristics and Applications of Steel Products for Hydropower Generation

1. High Strength and Durability

1.1 Tensile Strength

Steel used in hydropower generation must withstand the dynamic loads of components such as turbine blades and pressure pipelines. High-strength low-alloy steels (such as Q345E and Q420C) are typically used, with tensile strengths reaching 500-700 MPa, ensuring the structure does not deform under long-term water pressure impact.

1.2 Corrosion Resistance

By adding alloying elements such as chromium and nickel, or using epoxy resin coatings, the steel’s resistance to corrosion in humid environments is significantly improved, extending its service life to over 30 years.

1.3 Fatigue Resistance

For periodically stressed components such as turbine runners, the steel must possess a high fatigue limit. Heat treatment processes optimize the grain structure, reducing the risk of crack initiation.

2. Precision Machining and Welding Performance

2.1 Plasticity

The steel must meet the forming requirements of complex hydraulic components, such as guide vanes and spiral casings, achieving high dimensional accuracy (tolerance ±0.5mm) through controlled rolling and cooling processes.

2.2 Welding Compatibility

Low-hydrogen welding rods and preheating processes are used to ensure that the weld strength matches the base material, avoiding welding cracks and meeting the on-site assembly requirements of large hydropower stations.

3. Application Classification

3.1 Pressure Pipelines and Spiral Casings

High-strength steel is used to transport high-pressure water flows. For example, the Three Gorges Project uses Q420C steel to make a 12-meter diameter spiral casing that can withstand 1.5MPa water pressure.

3.2 Turbine Runners and Blades

Wear-resistant steel (such as ZGMn13) is used in rivers with high sediment content. Surface hardening treatment resists wear and improves power generation efficiency.

3.3 Gates and Support Structures

Weathering steel is used for open-air gates. Alloying forms a protective oxide layer, reducing maintenance costs.

4. Environmental Protection and Sustainability

4.1 Recyclability

The steel is 100% recyclable, reducing carbon emissions throughout the entire lifecycle of hydropower generation, aligning with the green energy concept.

4.2 Lightweight Design

High-strength steel is used to reduce component thickness, decreasing material consumption. For example, the Baihetan Hydropower Station’s turbine runner reduced its weight by 15%.

Through material innovation and process optimization, steel for hydropower generation has become a key material supporting the development of clean energy. Future development will focus on higher strength and better corrosion resistance.

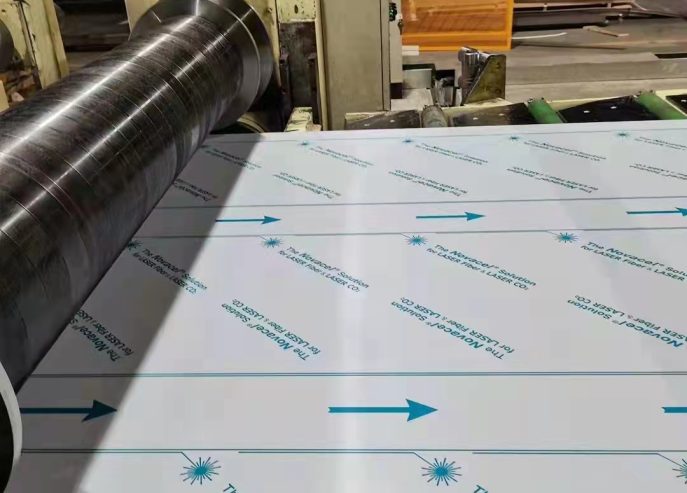

Processing & Packaging

Heat treatment (Q+T, annealing, stress relief)

Rough and final machining for shaft and flanges

UT/RT/MT with reports by SGS, TUV or per ASME/EN

Protective film for shipment

Marking: project code, heat no., size, batch

Seaworthy wooden box, steel saddle, or plastic wrap + pallet

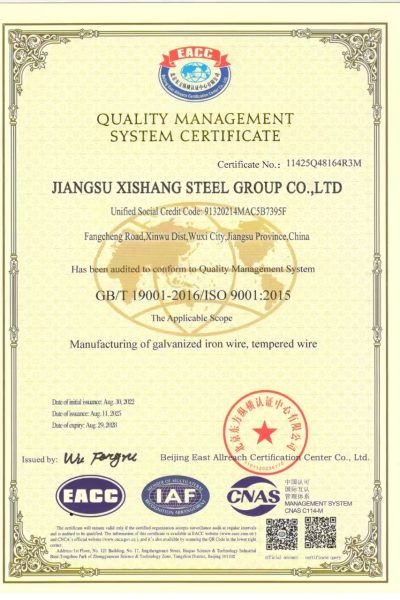

Why Buy From Xishang?

- Expertise in large forgings and heavy plates for power industry

- Grades with excellent weldability and low-temperature toughness

- 100% UT and mechanical property guaranteed

- Precise heat treatment and CNC machining for shafts

- Full project traceability & technical documents

- Support for trial piece before full production

Frequently Asked Questions

Q1: What steel grades are most common for turbine runners or shafts?

A:

30CrNiMo8, 20Mn5, and 42CrMo4 are common for forged shafts. For weldable components, Q345D/E or HY100 are often used.

Q2: Do you provide UT or third-party inspection reports?

A:

Yes. All hydropower steel is 100% ultrasonic tested and can be accompanied by SGS, BV, or customer-designated inspection.

Q3: Can you handle large shaft or ring forgings?

A:

Yes. Our capacity covers shafts up to 12m, forged rings to 3000mm diameter, and over 10 tons in weight.

Q4: What toughness level is guaranteed for plates?

A:

Charpy V-notch impact test at -20°C or -40°C is standard depending on grade.

Q5: Do you accept custom drawings or machining requests?

A:

Absolutely. We support rough and finish machining based on detailed project drawings.