- You are here:

- Home /

- Products /

- Alloy /

- Heat-Resistant Steel

Heat-Resistant Steel – Engineered for Elevated Temperatures & Thermal Fatigue Resistance

We supply a wide range of heat-resistant stainless and alloy steels for high-temperature environments such as furnaces, boilers, and reactors. Grades include austenitic, ferritic, martensitic, and Cr-Mo steels.

What Is Heat-Resistant Steel?

Heat-resistant steel refers to alloys that maintain mechanical strength, oxidation resistance, and thermal stability at high temperatures (500–1200°C). These steels are commonly used in thermal power, petrochemical, kilns, and industrial heating equipment.

Core Features:

Excellent creep strength,Resistance to thermal fatigue & deformation,Oxidation & carburization resistance, Long service life in cyclic heating environments.

Common Grades:

Austenitic: 310S, 253MA, 304H, 347H,2535Nb,RA330,314,309Si2

Ferritic/Martensitic: 1Cr13, 2Cr13

Cr-Mo: 12Cr1MoV, T91, P22, P91

Super Heat-Resistant: Incoloy 800H/HT, Alloy 625 (see superalloys)

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Product Forms | Sheet, plate, bar, pipe, tube, fittings, casting blanks |

| Thickness Range | 3mm – 100mm (plate) / Ø6–300mm (bar) |

| Pipe Sizes | NPS 1/2” – 24” (SCH 10 to 160) |

| Standard | ASTM A213 / A335 / A240 / EN 10028-2 / GB 5310 |

| Delivery State | Hot rolled, normalized, solution annealed |

| Surface Finish | Pickled, ground, black, machined |

* Heat treatment, PMI testing, and third-party inspection available on request.

Performance Characteristics and Applications of High-Temperature Resistant Stainless Steel Products

1. Performance Characteristics

1.1 High-Temperature Stability

High-temperature resistant stainless steel maintains stable mechanical properties, including creep resistance and fatigue resistance, under high-temperature environments, ensuring no significant deformation or failure during long-term high-temperature operation.

1.2 Oxidation Resistance

It possesses excellent oxidation resistance, forming a dense oxide film on the surface, effectively preventing further oxygen corrosion of the internal materials, thereby extending its service life.

1.3 Corrosion Resistance

It exhibits excellent chemical corrosion resistance in high-temperature corrosive environments (such as acids, alkalis, or salt spray), making it suitable for various harsh working conditions.

1.4 Low Coefficient of Thermal Expansion

A low coefficient of thermal expansion means high dimensional stability under drastic temperature changes, reducing the risk of cracks or deformation caused by thermal stress.

1.5 Mechanical Strength

It maintains high strength and hardness at high temperatures, making it suitable for applications subject to heavy loads or dynamic stress.

2. Applications

2.1 Industrial Furnaces

Components used in the manufacture of industrial furnaces such as heat treatment furnaces and smelting furnaces, including heating elements, furnace tubes, and supports, as they can withstand extreme temperatures without degradation.

2.2 Automotive Manufacturing

Applications in automotive exhaust systems, such as exhaust pipes and mufflers, utilizing their high-temperature and corrosion-resistant properties to optimize engine performance and reduce maintenance requirements.

2.3 Aerospace

Playing a critical role in aircraft engines and spacecraft components, such as blades and combustion chambers, ensuring reliable operation in high-speed, high-temperature environments.

2.4 Energy Equipment

Used in steam generators and heat exchangers in nuclear power plants and thermal power plants, improving energy conversion efficiency and enhancing equipment durability.

2.5 Chemical Equipment

In chemical reactors and pipelines, resisting high-temperature corrosive media, ensuring production safety and continuity.

High-temperature resistant stainless steel products, with their comprehensive properties, have become core materials in high-temperature industrial fields, widely used in many key industries, driving technological progress and efficiency improvements.

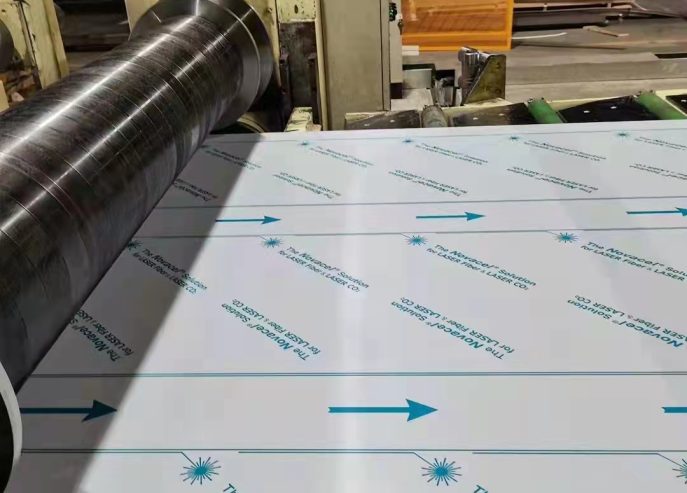

Processing & Packaging

Plasma / flame / waterjet cutting

Solution annealing or normalization

PMI, UT, hardness, creep test

Protective film / rust-proof oil

Steel strapping + wooden pallet or seaworthy crate

Heat number and batch number traceability

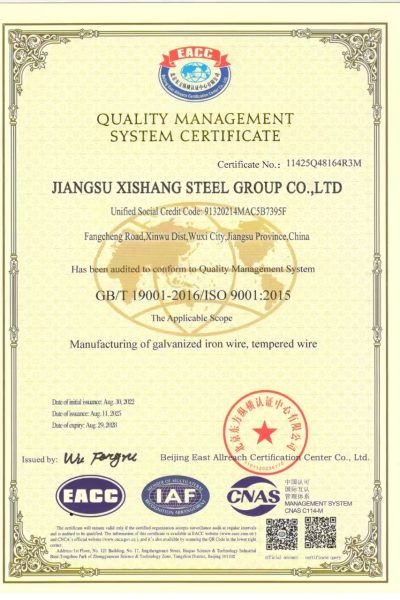

Why Buy From Xishang?

- Deep inventory of certified high-temp alloys

- Technical support for grade & application matching

- Low MOQ and fast production for urgent jobs

- Custom cutting, bending, threading, and surface treatments

- Export-ready packaging and inspection reports

- NDT, hardness & creep testing reports available

Frequently Asked Questions

Q1: What grade should I use for continuous service above 1000°C?

A:

For temperatures >1000°C, grades like 310S, 253MA or Incoloy 800H are preferred due to their excellent oxidation resistance and creep strength.

Q2: Can you provide 12Cr1MoV or P91 pipes for power plant use?

A:

Yes, we supply high-pressure alloy steel pipes for boiler and superheater systems, compliant with ASTM A335 or GB 5310.

Q3: Do you offer welding wire/filler for heat-resistant steel?

A:

Yes. Welding consumables (ER310, ER347, etc.) can be supplied upon request.

Q4: What’s the delivery time for heat-resistant alloy plates?

A:

Standard grades are in stock. For cut-to-size or rare alloys, 7–15 days is typical.

Q5: Are inspection certificates included?

A:

Yes. MTC (EN 10204 3.1 / 3.2), third-party SGS, TUV, or BV inspection available.

Let us know your required grade