- You are here:

- Home /

- Products /

- Alloy Steel /

- Special Stainless Steels /

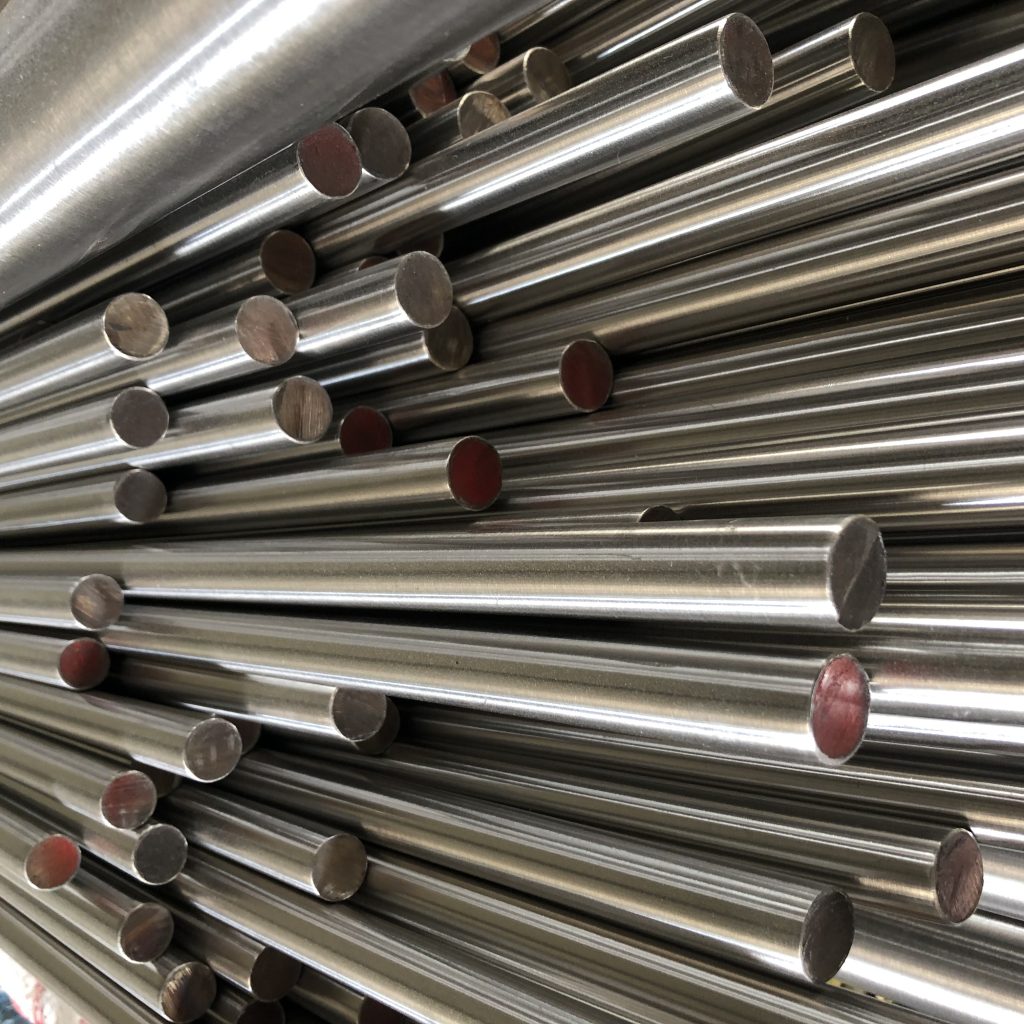

ASTM A193 Grade B8M 347H Stainless Steel Bar

- High-Temperature Performance: Stabilized with niobium (Nb) to prevent chromium carbide precipitation, maintaining corrosion resistance at 800-1500°F (427-816°C).

- Corrosion Resistance: Superior oxidation and scaling resistance in sulfur-rich environments.

- Weldability: Lower carbon content reduces intergranular corrosion risk post-weld.

Chemical Composition (wt%)

Element | Content Range |

C | ≤0.08 |

Si | ≤1.00 |

Mn | ≤2.00 |

P | ≤0.045 |

S | ≤0.030 |

Cr | 17.0-19.0 |

Ni | 9.0-13.0 |

Nb | ≥10×C |

Others | Fe Balance |

Property | Value |

Diameter Range | 10mm – 300mm |

Hardness (HB) | ≤187 |

Density | 7.93 g/cm³ |

Yield Strength | ≥35 ksi (241 MPa) |

Tensile Strength | ≥75 ksi (517 MPa) |

I. Material Properties

Chemical Composition

Basic Ratio: 18Cr-10Ni-0.1Nb (mass fraction)

Trace Elements: N ≤ 0.11% (controls intergranular corrosion)

Impurity Standard: Cu ≤ 0.75% (prevents thermal brittleness)

High-Temperature Performance

Creep Resistance: Time to Fracture ≥ 2000 h at 700°C/100 MPa

Thermal Fatigue Resistance: Cycle Life > 5000 cycles at ΔT = 500°C

Mechanical Parameters

High-Temperature Yield: ≥ 120 MPa at 800°C

Hardness Gradient: Hardness Drop ≤ 15% from 20°C to 600°C

II. Application Scenarios

Energy Sector

Ultra-supercritical Units: Main Steam Piping (Design Pressure ≥ 31 MPa) )

Nuclear Power Plant: Pressurizer Safety Terminal (Seismic Resistance Level 1E)

Chemical Equipment

Ethylene Cracking Furnace: Radiant Section Tubes (Carburization Resistance Thickness ≤ 0.5mm)

Sulfur Recovery Unit: High-Temperature Flanges (H₂S Corrosion Rate ≤ 0.1mm/year)

Special Environments

Offshore Platform: Desalination Heat Exchanger (Cl⁻ Concentration Tolerance ≥ 20,000ppm)

Biopharmaceutical: Fermentation Tank Agitator Shaft (Surface Roughness Ra ≤ 0.8μm)

III. Processing Guidelines

Heat Treatment Process

Solution Temperature: 1040-1120°C (Water Quenching)

Stabilization Treatment: 850-930°C (Air Cooling)

Welding Specifications

Compatible Welding Material: ERNiCrFe-7 (AWS A5.14)

Interpass Temperature: ≤ 150°C (To prevent σ phase precipitation)

Surface Treatment

- Polished: Ra ≤0.8μm for precision components.

- Pickled: Removes oxide scale for better corrosion resistance.

Why Choose Us ?

- Certified: ISO 9001, PED 2014/68/EU.

- Customizable: Tailored dimensions and heat treatments.

Applications & Industries

Aerospace:

High-power density actuators.

Electronics:

Precision sensors & MEMS components.

Energy:

Magnetic coupling devices for turbines.

Frequently Asked Questions

Q1: What is the max service temperature?

A1: 1500°F (816°C) in cyclic conditions.

Q2: Does it require post-weld annealing?

A2: Not typically due to Nb stabilization.

Q3: How to distinguish 347H from 347?

A: 347H has higher carbon content (≥0.04%) for enhanced high-temperature strength, while 347 (C≤0.08%) is for general corrosion resistance.

Q4: Surface treatment options?

A: Shot peening can refine surface grains to ~100nm, improving fatigue resistance.

Ready to source alloy steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.