- You are here:

- Home /

- Products /

- Alloy Steel /

- Special Stainless Steels /

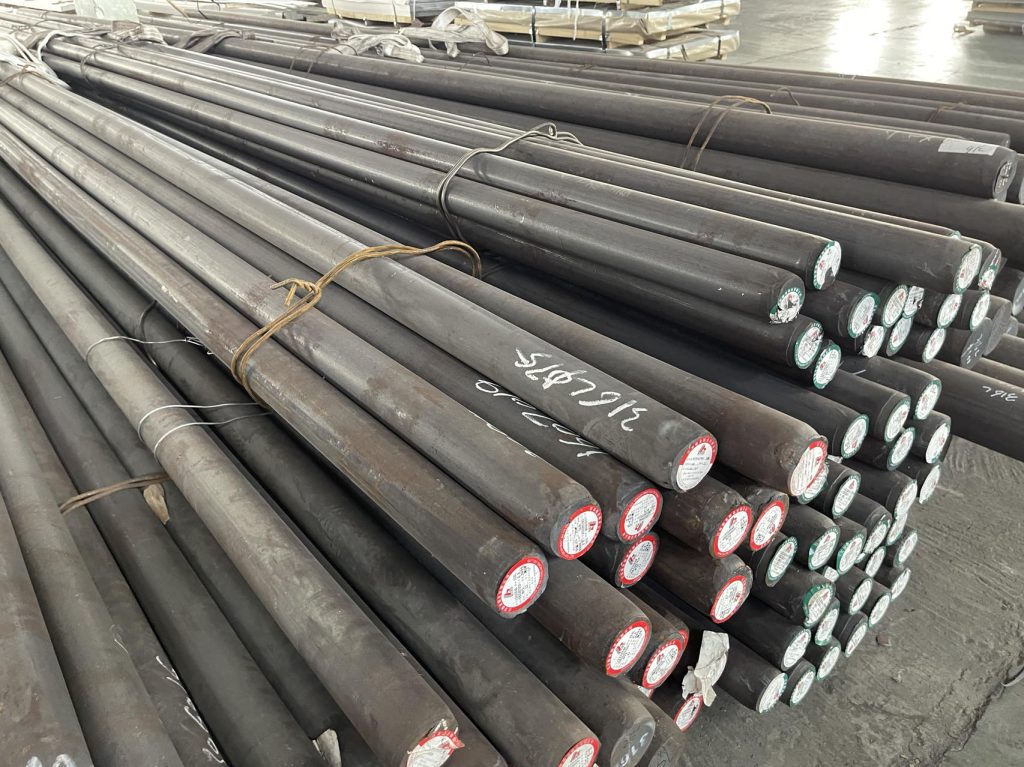

3Cr17Ni7Mo2N Bar (ASTM A276/A479 Grade 318)

- Corrosion Resistance: High resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride environments.

- Strength: Enhanced mechanical properties due to nitrogen (N) and molybdenum (Mo) alloying.

- Weldability: Moderate weldability with pre/post-heat treatment to avoid carbide precipitation.

Chemical Composition (wt%)

Element | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

Range | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.030 | 16.0-18.0 | 6.0-8.0 | 1.5-3.0 | 0.10-0.20 | ≤0.5 |

1. Performance Characteristics

Excellent Corrosion Resistance: Containing 17% chromium, 7% nickel, and 2% molybdenum, it is stable in both oxidizing and reducing media, and is particularly resistant to environments containing sulfur and chloride ions.

High Strength and Wear Resistance: Nitrogen strengthens the matrix, significantly improving hardness and wear resistance, making it suitable for high-load conditions.

High-Temperature Stability: The synergistic effect of molybdenum and nickel ensures that it maintains mechanical properties even at high temperatures, making it suitable for components in hot-processing equipment.

2. Core Advantages

Optimized Chemical Composition: The chromium-nickel-molybdenum-nitrogen combination offers a balanced combination of corrosion resistance, strength, and toughness, resulting in overall performance superior to that of ordinary stainless steel.

Processing Adaptability: Properties can be further adjusted through heat treatment to meet the customized needs of different industrial scenarios.

3. Main Applications

Petrochemical: Used in refining equipment, pipelines, and reactors, withstanding acidic media, high temperature, and high-pressure environments.

Energy: High-temperature components in nuclear and thermal power plants (such as turbine blades and pumps and valves) ensure long-term operational reliability.

Medical: Surgical instruments and implant materials that meet biocompatibility and corrosion resistance requirements.

Mechanical Manufacturing: Gears, shafts, and molds suitable for high-wear and high-stress operating conditions.

Surface Treatment

- Polishing: Ra ≤0.4 μm (mirror finish available)

- Pickling: Passivation per ASTM A967 for corrosion resistance

Why Choose Us ?

- Certification: ISO 9001, PED 2014/68/EU

- Customization: Precision machining and heat treatment services

Applications & Industries

Aerospace:

High-power density actuators.

Electronics:

Precision sensors & MEMS components.

Energy:

Magnetic coupling devices for turbines.

Frequently Asked Questions

Q1: Is this material weldable?

A: Yes, but use ER308L filler wire and post-weld annealing.

Q2: What is the maximum service temperature?

A: Up to 600°C in oxidizing environments.

Q3: How does nitrogen improve performance?

A:Nitrogen substitutes for carbon in the crystal lattice, increasing strength without sacrificing ductility. It also enhances localized corrosion resistance.

Q4: Can it replace 17-4PH steel?

Yes, but with trade-offs:

Pros: Better SCC resistance and lower cost.

Cons: Slightly lower hardness (HRC 35 vs. 17-4PH’s 40-45).

Q5: Certifications available?

Traceability: EN 10204 3.1/3.2, ISO 9001.

Special Cert: NACE MR0175 (for sour service).

Ready to source alloy steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.