- You are here:

- Home /

- Products /

- Galvanized Steel /

- Galvanized Steel Coil

High-Quality Galvanized Steel Coil for Roofing, Ducting & Construction

Hot-dip and electro-galvanized coils available in full thickness range with excellent corrosion resistance and spangle options. Ideal for roofing sheets, ducting, framing.

What Is Galvanized Steel Coil?

Galvanized steel coil is cold or hot rolled steel coated with a layer of zinc to provide corrosion resistance. It is one of the most common materials used in construction, HVAC, automotive, agricultural, and appliance manufacturing.

We supply:

Hot-dip galvanized coil (HDG) – strong zinc adhesion, longer outdoor lifespan

Electro-galvanized coil – smooth, precise coating, ideal for indoor or painted use

Zinc coating options: Z40–Z275 g/m²

Spangle options: regular, minimal, zero spangle

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Base Metal | Cold rolled / Hot rolled steel |

| Coating Type | Zinc (GI), or Zinc-Iron (Galvanneal) |

| Zinc Coating | 40–275g/m² |

| Thickness | 0.12mm – 3.0mm |

| Width | 600mm – 1500mm |

| Spangle Type | Regular / Small / Zero |

| Surface Treatment | Chromated, Oiled, Dry, Skin-passed |

| Inner Diameter | 508 / 610mm |

| Standard | ASTM A653 / JIS G3302 / EN 10346 |

* Optional: anti-fingerprint coating, tension leveling, slit coil supply.

Performance Characteristics and Applications of Galvanized Steel Coil

I. Performance Characteristics

(1)Corrosion Resistance

The dense zinc oxide film on the surface effectively isolates moisture and oxygen, significantly delaying steel corrosion in humid, acidic, and alkaline environments.

Zinc-iron alloy layers (such as zinc-aluminum-silicon coatings) further enhance heat resistance and corrosion resistance, making it suitable for high-temperature environments.

(2)Processing Performance

The base material is low-carbon steel, possessing excellent cold bending, stamping, and welding properties, meeting complex forming requirements.

The smooth surface of electro-galvanized steel sheet is suitable for deep drawing processes and is used in the manufacture of high-precision parts.

(3)Surface and Structural Characteristics

The coating has strong adhesion, facilitating subsequent painting or film coating treatments and enhancing decorative properties.

Lightweight design reduces material weight while maintaining structural strength.

(4)Environmental and Economic Efficiency

The zinc layer is recyclable during the production process, aligning with sustainable development principles.

The cost is lower than materials such as stainless steel, offering excellent cost-effectiveness.

II. Main Applications

(1)Construction Industry

Used in roofing, walls, light steel structures, and sandwich panels; its rust-proof properties extend building life.

(2)Home Appliance Manufacturing

Used in the outer casings and internal components of refrigerators, washing machines, air conditioners, etc., relying on its corrosion resistance and stamping properties.

High-end home appliances (such as ovens) use aluminized zinc-coated sheets, offering superior high-temperature resistance.

(3)Automotive Industry

Used in body panels, chassis parts, etc.; lightweight design reduces fuel consumption, while weldability ensures production efficiency.

(4)Other Fields

Used in traffic facilities (guardrails, signs), agricultural equipment, container manufacturing, etc., adapting to diverse environmental needs.

Used in traditional musical instruments, billboards, and other civilian products, balancing aesthetics and durability.

Galvanized coils, through the combination of zinc layer protection and substrate performance, have become an indispensable multi-functional material in modern industry.

Processing & Packaging

Slitting & edge trimming

Chromated/oiled surface conditioning

Eye to wall / eye to sky packaging

Waterproof + steel-strapped export bundling

Container loading with edge protectors

Why Choose Xishang?

- Full stock of Z40–Z275 coils in multiple thicknesses

- Slitting and custom width available

- Spangle control and surface finish customization

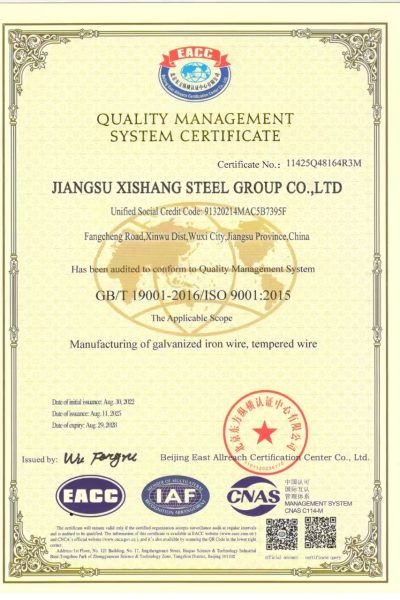

- SGS, BV, ISO certified with MTC

- Factory-direct pricing with low MOQ (3 tons)

- Fast lead time and international packing

Frequently Asked Questions

Q1: What is the difference between regular and zero spangle?

A:

Regular spangle has visible zinc crystal patterns; zero spangle has a smooth, uniform surface ideal for painting.

Q2: What’s the lifespan of galvanized coil outdoors?

A:

With Z275 coating, hot-dip galvanized coil can last over 20 years in mild climates.

Q3: Can I request a specific zinc coating weight?

A:

Yes, we support Z40 to Z275 based on corrosion resistance needs.

Q4: What’s the difference between HDG and electro-galvanized coil?

A:

HDG has thicker zinc and better corrosion resistance; electro-galvanized is thinner, smoother, and better for painting.

Q5: Do you offer small coil weights?

A:

Yes, we can produce coils as small as 1–3 tons per size with steel strapping.