- You are here:

- Home /

- Products /

- Stainless Steel /

- Stainless Steel Sheet /

- 309S Austenitic Heat-Resistant Stainless Steel

309S Austenitic Heat-Resistant Stainless Steel

309S is a high-chromium-nickel austenitic stainless steel engineered for elevated-temperature applications. Key characteristics include:

- Exceptional oxidation resistance: Sustained service up to 1100°C (2012°F), short-term exposure to 1150°C (2102°F).

- Superior thermal fatigue resistance: Performs under repeated thermal cycling.

- Excellent manufacturability: Compatible with welding, forming, and machining processes.

- Low-carbon design (S-grade): Carbon content ≤0.08% minimizes carbide precipitation and intergranular corrosion risks.

Technical Parameters (Chemical Composition, wt%)

| Element | Standard Range | Element | Standard Range |

|---|---|---|---|

| C | ≤0.08 | Cr | 22.0–24.0 |

| Si | ≤1.00 | Ni | 12.0–15.0 |

| Mn | ≤2.00 | Mo | ≤0.75 |

| P | ≤0.045 | N | ≤0.10 |

| S | ≤0.030 | Fe | Balance |

| Complies with ASTM A240/A480. Trace elements not listed are controlled per industry standards. | |||

309S Stainless Steel Sheet: Performance Characteristics and Core Applications

1. Performance Characteristics

1.1 High Temperature Resistance

It can be repeatedly heated below 980℃ and maintains continuous oxidation resistance in environments below 900℃. It exhibits excellent high-temperature strength and outstanding creep resistance.

Short-term temperature resistance can reach 1100℃, suitable for long-term high-temperature load scenarios.

1.2 Corrosion Resistance

The high chromium (23%) and nickel (13%) composition gives it the ability to quickly form an anti-oxidation layer, effectively resisting surface oxidation and corrosion, and adapting to various complex environments.

The low-carbon design reduces carbide precipitation, lowers the risk of intergranular corrosion, and improves weld stability.

1.3 Machining Characteristics

In the solution-treated state, it is non-magnetic; the sulfur content makes it easy to cut, suitable for high surface finish machining.

It has excellent weldability and can be welded using conventional methods, but its machinability is slightly inferior to grades such as 304 and 316.

2. Main Applications

2.1 High-Temperature Industrial Equipment

Boiler Manufacturing: Used for furnace linings, furnace tubes, and burner components to ensure structural stability under high-temperature environments.

Heat Treatment Equipment: Such as the feed inlet of drying furnaces and hot blast furnace tubes, meeting the requirements of repeated heating.

2.2 Chemical and Energy Sectors

Petrochemical Plants: Used for reactor linings and catalyst recovery systems, resisting acid and alkali corrosion.

Nuclear and Thermal Power: Manufactures steam turbine components, ensuring reliability in high-temperature and high-pressure environments.

2.3 Environmental and Public Welfare Applications

Waste Gas Treatment Equipment: Resists corrosion in sulfide environments, extending the lifespan of environmental protection equipment.

Food Processing Equipment: Such as cooking pots and storage tanks, meeting high-temperature disinfection and hygiene requirements.

3. Summary

309S stainless steel, with its excellent high-temperature corrosion resistance, stable mechanical properties, and easy processing characteristics, has become a core material in high-temperature industries, chemical and energy fields, and is widely used in boilers, petrochemical equipment, and environmental engineering, providing reliable solutions for extreme working conditions.

Surface Finishes

- Standard Finishes:

- 2B (Cold-rolled bright annealed), No.1 (Hot-rolled annealed & pickled), BA (Bright annealed)

- Bead blasting (Sa 2.5), Brushed (Directional/Random)

- Enhanced Treatments:

- Electropolishing (improved corrosion resistance)

- Passivation (strengthened oxide layer)

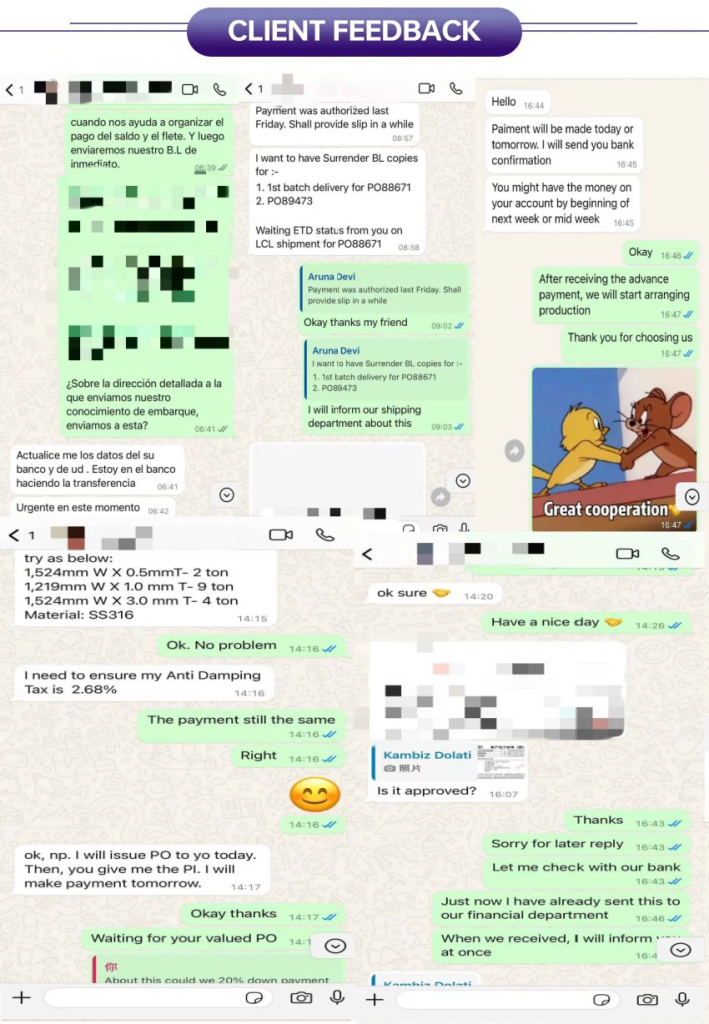

Why Choose Us ?

- Integrated ManufacturingFull-process control (Smelting → Hot Rolling → Cold Rolling → Finishing).

- Certifications: ISO 9001, SGS, Mill Test Certificates (MTC), export compliance documentation.

- Customization:Non-standard sizes (0.1–50mm thickness), tailored surface finishes.

- Global Logistics:30-day delivery guarantee, FOB/CIF terms supported.

Applications & Industries

Thermal Processing

Furnace rolls, radiant tubes, burner liners

Food Processing

Baking conveyors, high-temperature ovens

Power Generation

Boiler parts, flue gas systems

Petrochemical

Cracking furnace tubes, heat exchangers

Automotive

Exhaust systems, turbo housing components

Workshop & Packaging (Illustrative)

- Production Workshop:

- Image caption: CNC plasma cutting + automated welding line

- Packaging Standards:

- PE-coated moisture-proof wood crates

- Edge-protected coil bundling

- Custom labeling (Material grade/Batch No./Anti-corrosion warnings)

Frequently Asked Questions

Q1: How does 309S differ from 310S?

A: 309S has lower Cr/Ni (310S: Cr 24-26%, Ni 19-22%), making it cost-effective for ≤1100°C applications. 310S offers superior oxidation resistance (up to 1200°C).

Q2: Are special welding consumables required?

A: Use 309L-grade fillers (e.g., ER309LSi) to prevent carbide precipitation at weld zones.

Q3: Can 309S replace 316L in corrosive environments?

A: Not recommended. 316L contains molybdenum (2-3%) for chloride resistance, while 309S excels in high-temperature oxidation resistance.

Q4: What industries commonly use 309S stainless steel sheets?

A: Primarily used in petrochemical, chemical, and metallurgical industries for high-temperature and corrosive environments, such as furnace tubes, heat exchangers, and catalyst towers.

Q5: What are the welding considerations for 309S?

A: Suitable for common welding techniques; titanium content helps prevent intergranular corrosion during welding.

Ready to source stainless steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.