- You are here:

- Home /

- Products /

- Alloy Steel /

- Urea-Grade Steel /

724L Seamless Tube

- Corrosion Resistance: High chromium-nickel content ensures excellent resistance to acids, alkalis, and chlorides.

- High-Temperature Performance: Stable mechanical properties up to 800°C, suitable for thermal cycling environments.

- Weldability: Low carbon content (<0.03%) minimizes carbide precipitation, enhancing post-weld corrosion resistance.

Material properties and manufacturing process

724 seamless pipe is made of 724LN stainless steel (UNS S31726), which is a low-carbon, high-molybdenum austenitic stainless steel. The composition uniformity is ensured by vacuum melting process. Its core properties include:

(1) Corrosion resistance: It performs well in strong corrosive media such as urea melt and ammonia water, which is better than ordinary 316L stainless steel;

(2) Low temperature toughness: It still maintains good ductility at -196℃ and is suitable for deep cold working conditions;

(3) Welding performance: TIG/MIG process is required, and the joint oxide needs to be thoroughly cleaned before welding.

Performance advantages

(1) High pressure tolerance: The seamless structure has no weld defects and the pressure bearing capacity is above 1.2MPa, which is suitable for high temperature and high pressure environment;

(2) Surface treatment compatibility: The corrosion resistance can be improved by pickling and passivation, or hot-dip galvanizing can enhance the adaptability to high humidity environment in agriculture;

(3) Dimensional accuracy: The inner wall smoothness Ra≤0.8μm, which reduces the fluid conveying resistance.

Typical application areas

1. Chemical equipment

(1) Urea synthesis tower, reactor lining pipe, resistant to 190℃ high-pressure corrosive media;

(2) Ammonia pipeline, resistant to liquid ammonia stress corrosion cracking.

2. Energy and infrastructure

(1) Polyurethane insulation pipe working layer, used for heating/cooling fluid transportation at -50℃~120℃;

(2) Large diameter fluid pipe (DN≥300mm), for transportation of oil, natural gas, etc.

3. Special environment

(1) Agricultural greenhouse heating pipe, resistant to humidity above 90% after galvanizing;

(2) Heavy machinery workshop heat dissipation pipe, resistant to vibration and zero leakage for five years.

Chemical Composition

Element | C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

Range | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 24-26 | 5.5-7.5 | 1-2.5 | ≤0.5 |

Surface Treatment

- Pickling: Removes oxide scales, passivates surface.

- Polishing: Available in 180# to 600# grit for aesthetic/functional requirements.

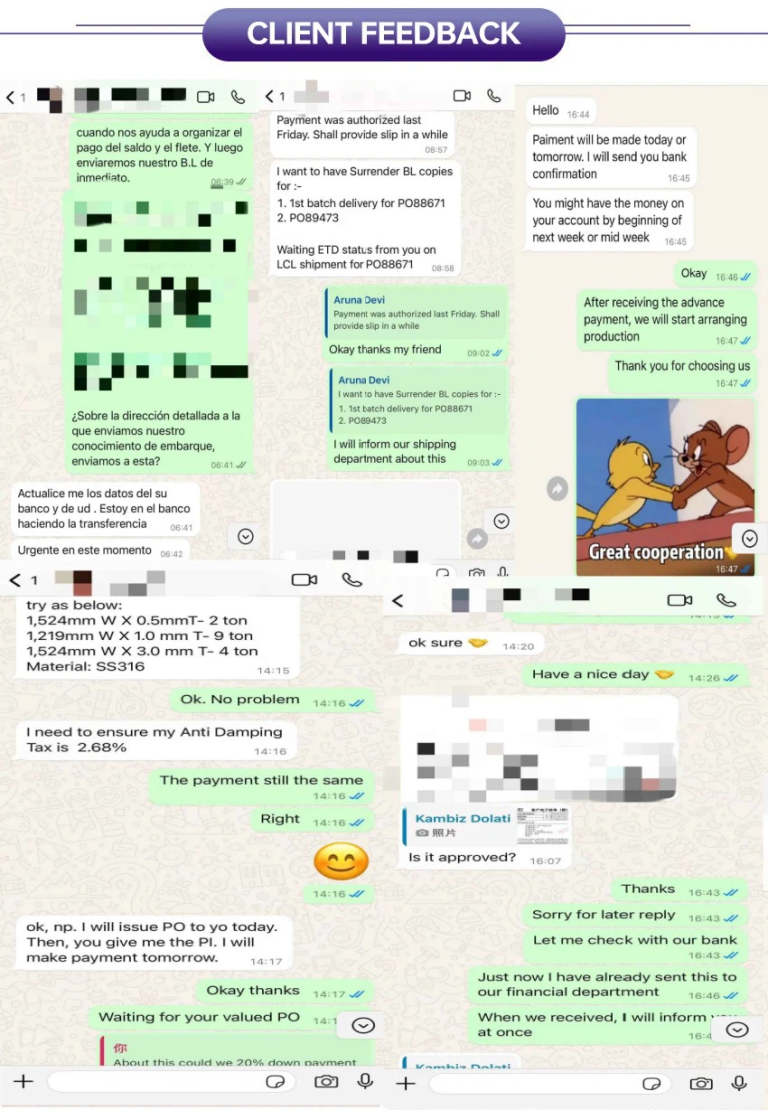

Why Choose Us ?

- Certified: ISO 9001, PED 2014/68/EU.

- Customization: Tailored dimensions and heat treatment.

- Global Logistics: Timely delivery with L/C/T/T options.

Applications & Industries

Chemical and petrochemical industries:

Used in the manufacture of chemical equipment, heat exchangers, piping systems, etc.

Urea production:

Particularly suitable for urea production equipment, such as urea synthesis towers, high-pressure ammonium carbamate condensers, urea solution heaters, etc.

Energy:

Components used in the manufacture of boilers, pressure vessels, and nuclear power plants.

Frequently Asked Questions

Q1: Does 724L require post-weld annealing?

A1: Not typically for thin sections (<5mm).

Q2: How is 724L seamless tubing manufactured?

A: The production process involves:

-

Hot rolling: Steel billet is heated and passed through rollers to form a hollow tube.

-

Cold drawing: The tube undergoes further processing to achieve precise dimensions and surface finish.

-

Heat treatment: Annealing or tempering is applied to enhance mechanical properties.

-

Quality control: Non-destructive testing (NDT) methods like ultrasonic inspection ensure defect-free output.

Q3: How is quality verified during production?

A: Mandatory tests include:

Ultrasonic testing (UT) for internal defects (GB/T 5777 C5 level).

Spectroscopic analysis for material consistency.

3D bending simulation for stress distribution validation.

Q4: What are the advantages of using 724L seamless tubing?

-

Superior strength: Seamless design eliminates weak points, making it ideal for high-pressure environments.

-

Corrosion resistance: 724L grade offers excellent resistance to oxidation and chemical exposure.

-

Precision: Tight tolerances ensure compatibility with complex assemblies.

-

Longevity: Enhanced durability reduces maintenance costs over its lifecycle.

Q5: How to select the right 724L seamless pipes for a project?

Consider factors such as:

-

Operating conditions: Temperature, pressure, and exposure to corrosive substances.

-

Mechanical requirements: Tensile strength, elongation, and hardness.

-

Regulatory compliance: Ensure adherence to industry-specific standards (e.g., ASME, API).

-

Supplier expertise: Choose manufacturers with proven experience in high-grade tubing production.

Ready to source alloy steel from a trusted Chinese manufacturer?

Let us support your project with reliable quality, fast delivery, and expert service.

Get a quote today — we usually respond within 12 hours.