- You are here:

- Home /

- Products /

- Alloy /

- Super Austenitic Stainless Steels

Super Austenitic Stainless Steels – Corrosion Resistance Beyond 316L

High-performance stainless steels with exceptional pitting resistance and durability for seawater, acid, and high-chloride environments. Trusted in offshore, chemical, and cleanroom applications.

What Is Super Austenitic Stainless Steel?

Super austenitic stainless steels are a class of high-alloyed, nitrogen-enhanced austenitic grades that offer superior corrosion resistance compared to standard 304/316.

These grades are characterized by:

Very high chromium, molybdenum, and nickel content

Fully austenitic structure, with optional nitrogen to increase strength

Excellent resistance to pitting (PREN ≥ 40), crevice, and stress corrosion

Ideal for aggressive chemical and chloride-rich environments

Key Grades:

| Grade | PREN | Main Feature |

|---|---|---|

| 254SMO (S31254) | 42–45 | Excellent pitting resistance, seawater approved |

| 654SMO (S32654) | >50 | One of the highest corrosion-resistant grades |

| 904L (N08904) | 35 | Acid and chloride resistant, copper added |

| 1925hMo / 1925hN | 44–46 | Excellent crevice and intergranular corrosion resistance |

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

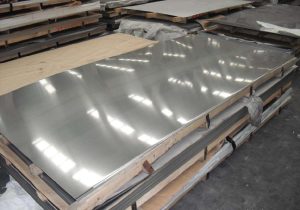

| Forms Available | Plate, sheet, bar, tube, pipe, flange, fitting |

| Standards | ASTM A240, A312, A182, EN 1.4547 / 1.4539 / 1.4565 |

| Plate Thickness | 3mm – 100mm |

| Pipe Size | NPS 1/2” – 24”, SCH10 – SCH160 / XXS |

| Bar Diameter | Ø6mm – 300mm |

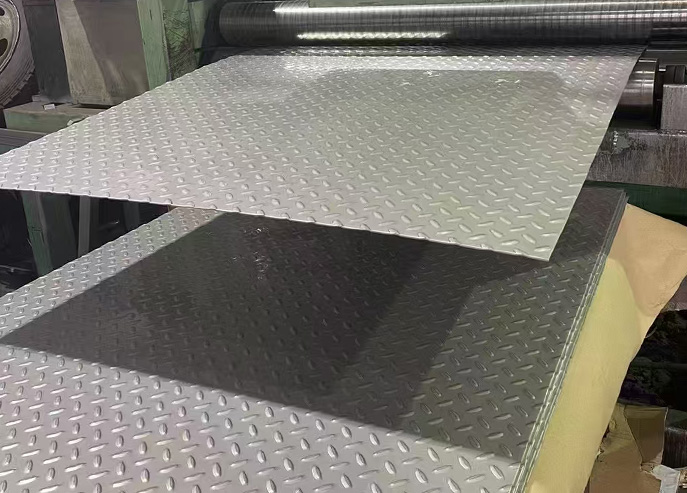

| Finish Options | 2B, No.1,NO.4, HL, BA, pickled, mirror polish |

| Condition | Solution annealed |

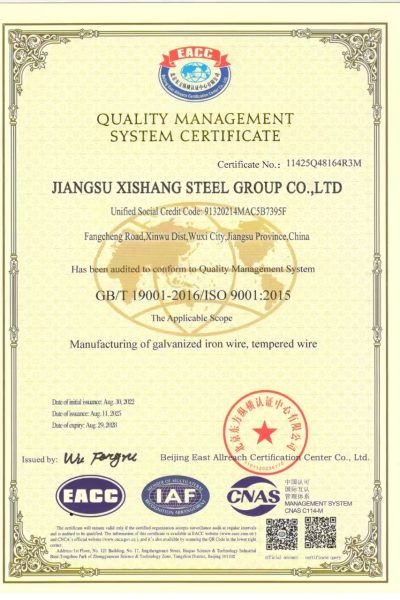

| Certifications | EN10204 3.1 / 3.2, NORSOK, PED, NACE MR0175 |

Product Forms: Plate, tube, pipe, bar, flange, forging 100% PMI-tested and intergranular corrosion-tested (per ASTM A262)

Performance Characteristics and Applications of Super Austenitic Stainless Steel

Super austenitic stainless steel is a high-performance alloy material. By adding elements such as molybdenum and nitrogen, its overall performance is enhanced, making it widely used in extreme environments. Its core characteristics and applications are as follows:

1. Performance Characteristics

1.1 Excellent Corrosion Resistance

Extremely strong resistance to pitting and crevice corrosion in chloride environments, suitable for seawater, chemical media, and other scenarios.

Excellent resistance to uniform corrosion, exhibiting outstanding performance in acids such as sulfuric acid and phosphoric acid.

1.2 High Strength and Toughness

Nitrogen-containing design significantly improves yield strength while maintaining good ductility, adapting to high-stress conditions.

Maintains stable mechanical properties at high temperatures, suitable for hot working applications.

1.3 Excellent Machining Performance

Good cold and hot working performance, allowing for the formation of complex parts through forging, rolling, and other processes.

Excellent weldability; reliable connections can be achieved using standard austenitic stainless steel welding methods.

2. Main Applications

2.1 Marine Engineering and Shipbuilding

Used in seawater desalination equipment, ship propellers, etc., to resist seawater corrosion.

2.2 Chemical and Energy Industries

Manufacturing chemical reactors and heat exchangers to handle highly corrosive chemicals.

Applications in nuclear power plant piping systems to ensure long-term safe operation.

2.3 Environmental Protection and Medical Equipment

Components for wastewater treatment plants, resistant to biological and chemical corrosion.

Medical implants and surgical instruments, meeting biocompatibility requirements.

2.4 High-End Industrial Applications

Aerospace fasteners, balancing lightweight and strength requirements.

Food processing machinery, meeting hygiene standards and resistant to detergent corrosion.

Super austenitic stainless steel, with its comprehensive properties, has become an indispensable material choice in modern industry.

Processing & Packaging

Waterjet / plasma / laser cut available

Bright annealed / pickled / mirror polishing/embossed

PMI, UT, IGC (A262), and mechanical testing

Marked with grade, size, heat no. & QR code

Export-ready crate, pallet or seaworthy packaging

Why Buy From Xishang?

- Full range of super austenitic stainless grades in stock

- Customized cutting, forming, machining services

- Support for sour service, NACE & offshore certifications

- Traceability: MTC, heat number, batch ID, lab tests

- Global export packaging + fast logistics

- Small MOQ available for project trials or maintenance

Frequently Asked Questions

Q1: How does 254SMO compare to 316L?

A:

254SMO offers more than 2–3x the pitting resistance (PREN 42 vs 25), and superior performance in seawater and aggressive chloride environments.

Q2: Is 904L still suitable for sulfuric acid resistance?

A:

Yes, especially where reducing acids like H₂SO₄ or mixed environments exist. 904L’s copper content improves resistance.

Q3: Do you offer 654SMO for seawater?

A:

Yes. We stock and machine 654SMO (S32654) for the most demanding seawater or FGD applications.

Q4: Can I order polished super austenitic tubes?

A:

Yes. Tube polish options include 180–600 grit, mirror or sanitary finishes.

Q5: What is your standard delivery time?

A:

For stocked items: 3–5 days. Custom cut: 5–10 working days depending on size/volume.