- You are here:

- Home /

- Products /

- Alloy /

- Hastelloy Alloy

Hastelloy Alloys – Extreme Corrosion Resistance for Aggressive Chemical Environments

Nickel-molybdenum-chromium-based Hastelloy alloys offer unmatched corrosion resistance in both oxidizing and reducing environments. Ideal for chemical plants, pharmaceuticals, and marine systems.

What Is Hastelloy?

Hastelloy® is a trademarked family of nickel-based superalloys developed by Haynes International. These alloys are engineered to resist highly aggressive chemical media, such as:

Hydrochloric acid,Sulfuric acid,Ferric chloride,Sodium hypochlorite,Acetic & phosphoric acids.

Its superior thermal stability, stress corrosion cracking resistance, and pitting resistance make it ideal for extreme conditions where stainless steel or lower alloys fail.

Popular Grades:

C-276 – Most versatile grade for oxidizing/reducing media

C-22 – Higher resistance to oxidizing agents like nitric acid

B-2 / B-3 – Excellent in hydrochloric and non-oxidizing acids

X / G30 / G35 – Niche applications in fertilizer, pickling & heat exchangers

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Forms Available | Sheet, plate, rod, pipe, tube, wire, fittings, flanges |

| Grades | Hastelloy C-276, C-22, C-2000, C-4, B-2, B-3, G-30, X, G-35 |

| Standard | ASTM B575 (sheet), B622 (pipe), B574 (bar), B619/B626 (welded tube) |

| Sheet Thickness | 0.5mm – 50mm |

| Bar Diameter | 6mm – 250mm |

| Pipe Sizes | 1/8" – 12" NPS / SCH 10–160 |

| Condition | Annealed, pickled, bright polished, rough turned |

* Certificates: EN 10204 3.1 / 3.2, NACE MR0175, TUV, SGS available.

Hastelloy Alloy Products: Performance Characteristics and Applications of High-Temperature Resistant Stainless Steel

Hastelloy alloys are a class of high-performance nickel-based corrosion-resistant alloys designed for extreme environments and widely used in chemical, energy, and aerospace fields. Their core advantages lie in their superior high-temperature resistance and corrosion resistance, especially in strong acid, strong alkali, and high-temperature oxidizing environments. The following is a detailed analysis of their performance characteristics and applications:

1. Performance Characteristics

1.1 High-Temperature Resistance

High-Temperature Stability: Hastelloy alloys maintain structural integrity above 1000°C, exhibiting significantly higher high-temperature strength than ordinary stainless steel, making them suitable for long-term high-temperature operating environments.

Oxidation Resistance: A dense oxide film forms on the surface, effectively resisting high-temperature oxidation and extending equipment life.

1.2 Corrosion Resistance

Chemical Stability: Extremely resistant to strong acids (such as sulfuric acid and hydrochloric acid), strong alkalis, and salt solutions, reducing equipment failure caused by corrosion.

Resistance to Stress Corrosion Cracking: Excellent performance in harsh media such as chloride ions, suitable for chemical reactors.

1.3 Mechanical Properties

High Strength and Toughness: Maintains high strength and good ductility even at high temperatures, with outstanding creep resistance, suitable for dynamic load applications.

Processing Performance: Can be forged, welded, and cold-worked, facilitating the manufacture of complex components.

2. Main Applications

2.1 Chemical Industry

Reactors and Piping: Used in the manufacture of corrosion-resistant reactors and conveying systems to handle strong acid and alkali media, improving production safety and efficiency.

2.2 Energy Sector

Nuclear Energy Equipment: Used as a structural material in nuclear reactors, withstanding high-temperature and high-pressure environments to ensure long-term stable operation.

Petroleum Refining: Used in high-temperature and high-pressure reactors and pipelines to resist corrosion from sulfur-containing crude oil.

2.3 Aerospace

Engine Components: Used in the manufacture of turbine blades and combustion chambers to withstand extreme thermal loads, improving engine reliability and lifespan.

2.4 Environmental Protection and Medical Applications

Exhaust Gas Treatment Systems: Resistant to corrosion in high-temperature exhaust gas treatment, reducing maintenance requirements. Medical Devices: Used in surgical instruments and implants, balancing biocompatibility and corrosion resistance.

Conclusion

Hastelloy alloys, through their unique combination of properties, have become key materials for extreme environments, driving industrial technological progress. In the future, with the development of materials science, their applications will further expand.

Processing & Packaging

Water jet, plasma or laser cutting

Pipe threading, grooving, welding (GTAW)

Surface pickling, brushing, mirror polishing

Wood box packaging with desiccant

ID barcode, heat number, test report per bundle or coil

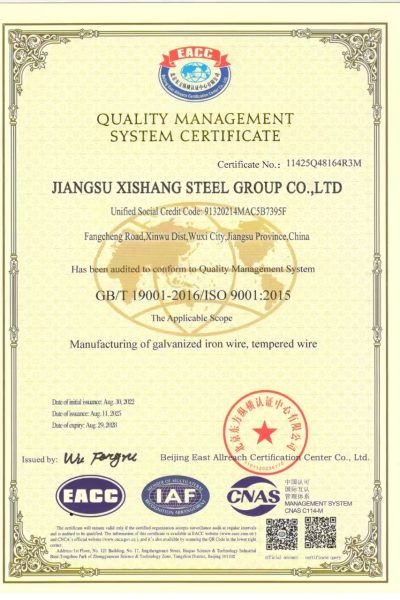

Why Buy From Xishang?

- Complete Hastelloy product range: sheet, bar, pipe, flange

- Deep stock of C276, C22, and B-2 alloys

- Support for cutting, bending, threading and CNC machining

- Compliance with international standards (ASTM / NACE / DIN)

- MOQ flexibility for urgent or development orders

- Export-grade packaging and global shipping

Frequently Asked Questions

Q1: What is the difference between Hastelloy C-276 and C-22?

A:

C-22 offers better resistance to oxidizing agents like nitric acid, while C-276 is the most versatile for both oxidizing and reducing conditions.

Q2: Can Hastelloy withstand hydrochloric acid?

A:

Yes. Grades like B-2 and B-3 are specifically resistant to hydrochloric acid, even in high concentrations.

Q3: Do you support export of pressure vessel certified Hastelloy?

A:

Yes, we provide 3.1 / 3.2 MTC and support EN, ASME code stamping via partners if needed.

Q4: What is the minimum quantity I can order?

A:

MOQ can be as low as 10kg for stock material or 1 piece of cut sheet/bar.

Q5: Is machining Hastelloy difficult?

A:

It requires slow speeds and carbide tools. We offer CNC service with expert parameters for Hastelloy grades.