- You are here:

- Home /

- Products /

- Alloy Steel /

- Cobalt Based Alloy

Cobalt-Based Alloys – Engineered for Heat, Corrosion & Wear Resistance

We supply cobalt alloys such as Stellite, Haynes, and custom cobalt-chromium compositions for extreme environments. Ideal for aerospace, turbines, medical implants, and industrial tools.

What Is a Cobalt-Based Alloy?

Cobalt-based alloys are high-performance metal materials composed primarily of cobalt, along with chromium, molybdenum, tungsten, and nickel. They are known for exceptional:

✅ High-temperature strength (retains strength up to 1000°C)

✅ Superior corrosion resistance

✅ Excellent wear and galling resistance

✅ Biocompatibility (in certain alloys)

Products Link

- Alloy >>

- Heat-Resistant Steel

- Inconel Alloys

- Urea-Grade Steel

- Titanium Alloys

- Superalloys

- Super Duplex Stainless Steels

- Special Stainless Steels

- Soft Magnetic Alloys

- Precipitation Hardening Stainless

- Hydropower Steel

- Incoloy Alloys

- Super Austenitic Stainless Steels

- High-Strength Steels

- Monel Alloys

- Hastelloy Alloy

- Cobalt Based Alloy

- Stainless Steel >>

- Galvanized Steel >>

- Carbon Steel >>

- Aluminum Steel >>

Optional product specifications

| Property | Details |

|---|---|

| Forms Available | Rod, bar, sheet, wire, casting blank, forging, powder |

| Grades | Stellite 6, 12, 21, 31 / Haynes 25, 188 / F75, F90, CoCrMo |

| Shapes | Round, flat, square, machined or forged blanks |

| Sizes | Rod: Ø4–200mm / Sheet: 0.5–50mm / Custom sizes |

| Standard | ASTM F75, F90, AMS 5387, ISO 5832-12 |

| Finish | Ground, polished, black, bright, solution-annealed |

* Powder metallurgy and CNC-prepared blanks available on request.

Applications

- Aerospace & Jet Engines – combustors, nozzles, bearings

- Medical Implants – orthopedic and dental alloys (CoCr)

- Valve Seats & Wear Parts – high-temperature corrosion & erosion

- Nuclear & Energy Systems – high-strength at elevated temperatures

- Petrochemical & Tooling – cutters, dies, corrosion-critical tools

Cobalt alloys are a class of alloy materials with cobalt as the main component, combined with elements such as chromium, nickel, molybdenum, and tungsten. Due to their unique performance characteristics, they occupy an important position in many industrial fields. The following is a detailed analysis of their performance characteristics and applications:

1. Performance Characteristics

1.1 High-Temperature Performance

Cobalt alloys exhibit excellent performance at high temperatures, possessing extremely high melting points and thermal stability. They maintain structural integrity under extreme temperatures and exhibit excellent resistance to creep and thermal fatigue.

1.2 Wear Resistance and Hardness

Cobalt alloys have high hardness and outstanding wear resistance, capable of withstanding high loads and frictional wear, making them suitable for high-wear environments.

1.3 Corrosion Resistance

With the addition of elements such as chromium, cobalt alloys exhibit good corrosion resistance in acidic and alkaline media, extending their service life.

1.4 Magnetic Properties

Some cobalt alloys possess high magnetic energy product and coercivity, making them ideal for manufacturing permanent magnet materials.

2. Applications

2.1 Aerospace

Used in the manufacture of critical components such as turbine blades and combustion chambers, these components withstand high-temperature and high-pressure environments to ensure efficient and stable engine operation.

2.2 Medical Devices

Cobalt-chromium alloys are widely used in artificial joints, dental implants, etc., due to their biocompatibility and wear resistance, reducing patient rejection reactions.

2.3 Energy Industry

In oil drilling, cobalt alloy tools are corrosion-resistant and high-temperature resistant, improving drilling efficiency; in the nuclear energy field, they are used in reactor components to withstand radiation and high temperatures.

2.4 Electronic and Magnetic Materials

Used in the manufacture of high-performance permanent magnets, such as rare-earth cobalt permanent magnet materials, applied in electronic equipment, wind turbines, etc., to improve energy efficiency and performance.

2.5 Other Industrial Applications

Including chemical equipment, automobile manufacturing, etc., utilizing their corrosion resistance and wear resistance to improve equipment reliability and lifespan.

With its excellent comprehensive properties, cobalt alloys have become an indispensable material in modern industry, continuously driving technological progress and innovation.

Processing & Packaging

Precision surface grinding and polishing

Ultrasonic & PMI testing before dispatch

Anti-rust oil + vacuum sealed plastic wrap

Packed in wooden boxes or crates with ID labels

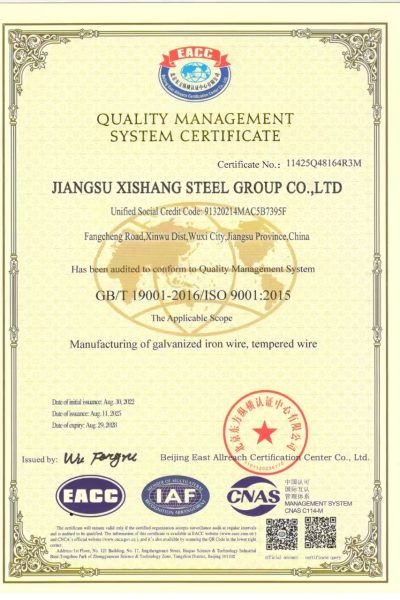

Why Choose Xishang?

- Full range of cast and wrought cobalt alloys

- Strict quality control with spectrometer and ultrasonic testing

- International certifications: ISO 13485, ASTM F75, CE (for medical)

- CNC machining + custom tolerance finishes

- Small batch trial supported with fast delivery

- Application consulting for special wear/corrosion environments

Frequently Asked Questions

Q1: What’s the main difference between Stellite and Haynes alloys?

A:Stellite is best for wear and erosion resistance; Haynes is preferred for high-temperature and oxidation environments.

Q2: Are cobalt alloys suitable for implants?

A:Yes, ASTM F75 and CoCrMo alloys are widely used in hip, knee, and dental implants due to biocompatibility.

Q3: Can you provide forged cobalt alloy blanks?

A:Yes. We supply both forged bars and cast + CNC machined forms.

Q4: Do you support small quantity or R&D orders?

A:Absolutely. We accept low-MOQ orders for testing or development.

Q5: What is the typical hardness of Stellite 6?

A:HRC 38–44 (as-cast), can reach 50+ after work hardening.